Products

Hydraulic details

Hydraulic pumps and components 、 hydraulic motors 、 hydraulic cylinders 、 control valves

Description

marker

Introduction to the product

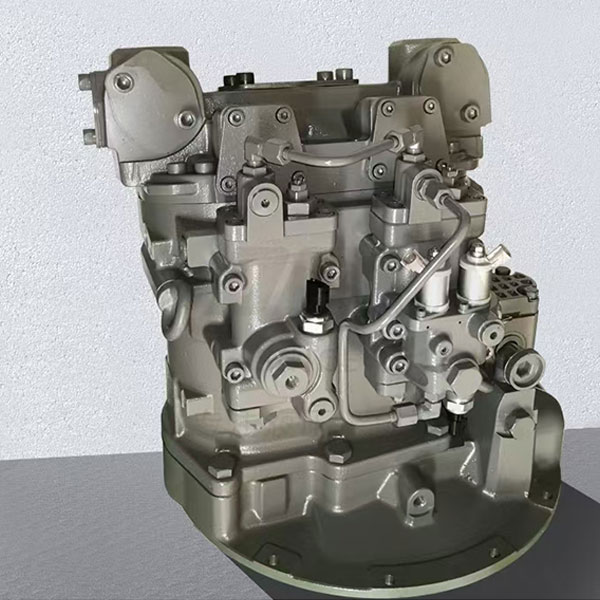

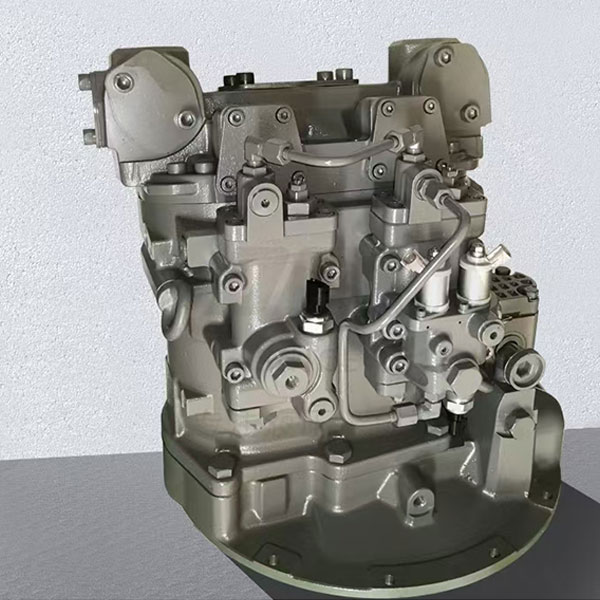

Hydraulic pumps and components

1. Hydraulic pump (pumping group): is the main element of the hydraulic system that converts mechanical energy into hydraulic and provides energy system. For example, the Hitachi HPV118 pump uses a design with two pumps connected in parallel, with an axial piston pump.

2. The components of the hydraulic pump: include the main shaft, additional shaft, central shaft, connecting connecting rods, pistons, large springs, housing, distribution discs and other elements. The quality of these components directly affects the performance and service life of the hydraulic pump.

Hydraulic motors

1. The rotary motor: connects the upper and lower parts of the machine, providing the 360-degree rotation of the upper part of the excavator. It consists of a motor itself and a gearbox, has a high carrying capacity and accuracy of rotation.

2. Motor of the chassis: provides energy for the movement of the excavator. It consists of a motor and a gearbox, has a high torque, strong traction and good reliability.

Hydraulic cylinders

1. The cylinder of a large lever: controls the rise and lowering of the large lever of the excavator, being one of the key elements for the performing excavation operations. Subject to high pressure and load.

2. The cylinder of the small lever: controls the nomination and drawing of a small lever, interacts with the cylinder of the large lever and the bucket cylinder for accurate control of the working range and movements of the excavator. Requires high tightness and wear resistance of the piston rod.

3. Bucket cylinder: used to control the opening and closing of the bucket, which directly affects the effectiveness and power of excavation. The quality of his work is of great importance for the general quality and efficiency of the excavator.

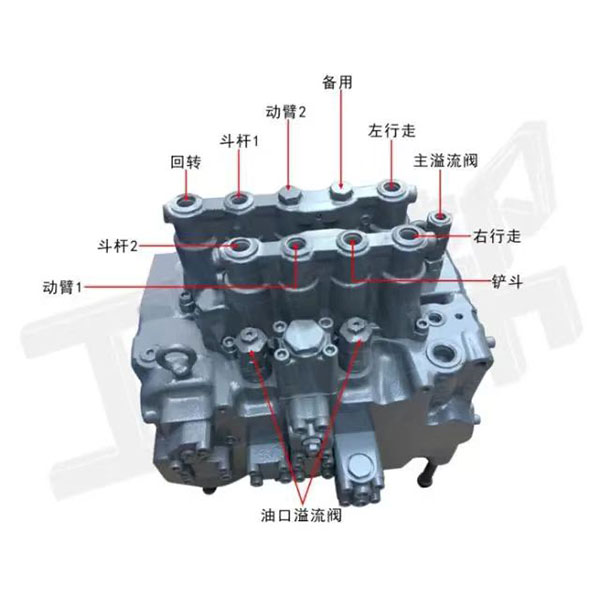

Control valves

1. Distribution valve: also known as a multi -circuit valve. It distributes the hydraulic fluid supplied by the pump, between different performing mechanisms, such as hydraulic motors and cylinders, which allows the excavator to perform various movements. It requires high accuracy in the control of the flow and pressure of the fluid.

2. Object valve: designed to limit maximum pressure in the hydraulic system to protect the system elements from damage at too high pressure. When the pressure in the system exceeds the given limit, the valve opens, and the excess fluids are dumped back into the tank.

3. Electromagnetic valve: controls the direction and turning on/off the flow of hydraulic fluid using an electric signal, providing accurate control of various elements of the hydraulic system, such as the control valves of the maximum flow of the pump and the control valve of the torque.