Hydraulic valve

Hydraulic valve- This is a device used to control the fluid flow in the hydraulic system. It plays the role of a 'switch' or 'switch', allowing you to either block or direct the fluid flow in the right direction. There are several typeshydraulic valves, each of which is intended to solve specific problems, for example, regulation of pressure, direction of flow or ensuring the safety of the system.

The main types of hydraulic valves

There are many varietieshydraulic valvesbut the most common of them include:

Safety valves

Surprising valves (pressure valves) are designed to protect the hydraulic system from excess pressure. When the pressure exceeds the specified limit, the valve opens and drops an excess of liquid, preventing damage to the components of the system.

Reduction valves

Reduction valves (pressure reduction valves) are used to reduce pressure in a certain part of the hydraulic system. This is especially useful when individual components of the system require lower pressure than the rest of the system.

Finding valves

Flight valves (or unilateral valves) allow the liquid to flow in only one direction, preventing the reverse flow. They are often used to protect pumps and other sensitive components.

Distribution valves

Distribution valves (or valves of the flow direction) direct the fluid flow along various contours of the hydraulic system. They can be manual, mechanical, hydraulic or electric.

Throttle valves

Thread valves are used to regulate the fluid flow rate. They create resistance to the flow, which allows you to control the speed of hydraulic cylinders or motors.

The principle of operation of the hydraulic valve

Hydraulic valvesThey work using fluid pressure to move internal elements, such as spools or balls. When the pressure reaches a certain level or receives a control command, the valve opens or closes, changing the direction or intensity of fluid flow.

Consider an example with a safety valve. In normal condition, the valve is closed. When the pressure in the system rises to a critical level, the spring inside the valve is compressed, allowing the liquid to flow into the drain line. As soon as the pressure decreases to a safe level, the spring returns the valve to a closed position.

The use of hydraulic valves

Hydraulic valvesWidely used in various industries and equipment, including:

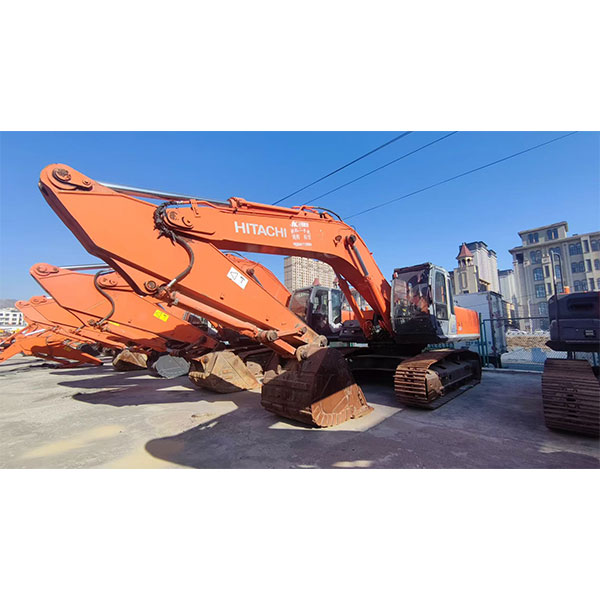

- Construction equipment: excavators, bulldozers, cranes (internal Mongolia Zhitsyan Construction equipment, https://www.nmgrq.ru/ offers a wide range of components for construction equipment, includingHydraulic valves).

- Agricultural equipment: tractors, combines, sprayers.

- Industrial equipment: presses, machines, casting machines.

- Aviation and space equipment: flight management systems, chassis.

- Automotive industry: steering systems, brake systems.

The choice of a hydraulic valve

When choosinghydraulic valveThe following factors must be taken into account:

- Valve type: Determine which type of valve is best suited for a specific task.

- Working pressure: Make sure the valve is designed for maximum pressure in the system.

- Fluid consumption: select a valve capable of passing the required volume of fluid.

- Type of control: Decide which type of control (manual, hydraulic, electric) is most suitable for your use.

- Operating conditions: Consider the temperature, humidity and other environmental factors.

Installation and maintenance of hydraulic valves

Proper installation and regular maintenancehydraulic valvesThey are crucial for ensuring reliable and durable operation of the hydraulic system. Follow the manufacturer instructions for the installation and regularly check the valves for leaks, damage or wear.

An example of using a safety valve

Suppose you have a hydraulic press working under a pressure of 200 bar. To protect the components of the press from overload, a safety valve configured for a pressure of 220 bar is used. If the pressure in the system exceeds 220 bar, the valve will open and drop the excess fluid, preventing damage to the cylinders and other press parts.

Comparison of various types of hydraulic valves

| Type of valve | Appointment | Advantages | Flaws |

|---|---|---|---|

| Safety | Protection against pressure on pressure | Simplicity of design, quick response | Does not provide pressure regulation |

| Reduction | Reduction in the pressure in the circuit | Accurate pressure adjustment | The complexity of the design |

| Back | Prevention of the reverse flow | Simplicity of installation, reliability | Does not regulate the flow |

| Distribution | Management of the direction of flow | Control flexibility, wide selection of structures | Dependence on the control signal |

Conclusion

Hydraulic valvesThey are important components of hydraulic systems that provide fluid flow control and protect the system from overload. Correct choice, installation and maintenancehydraulic valvesGuaranteed the effective and reliable operation of hydraulic equipment.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Leading buyers of alternating current hydraulic units in China

- Municipal excavators

- Inch size hydraulic cylinder factories in China

- Chinese suppliers of the excavator handle cylinders

- OEM suppliers Excavator

- Cheap supplier order an excavator

- Chinese suppliers of hydraulic power units

- Suppliers of a high -quality mountain excavator

- Suppliers of hydraulic cylinders structures in China

- Cheap manufacturers of hydraulic working cylinders