Hydraulic cylinder of high loading capacity

High -loading hydraulic cylinders- These are powerful devices used to create linear motion and strength in heavy industrial applications. They are characterized by increased strength and ability to withstand extreme loads, providing reliable and efficient work in the most difficult conditions. Their use covers a wide range of industries, including construction, mining industry, metallurgy and others, where the movement and rise of heavy objects are required.

What is a high -loading hydraulic cylinder?

Hydraulic cylinder of high loading capacity- This is a hydraulic cylinder designed to work with very high loads. They are usually used in applications where great power is required for lifting, moving or holding heavy objects.

The main components

- Cylinder sleeve:A strong pipe containing a piston.

- Piston:The mobile element inside the sleeve, which converts hydraulic pressure into mechanical force.

- Piston rod:A metal rod connected to the piston, which transfers force to an external object.

- Seals:Prevent the hydraulic fluid leakage.

- Fitting:Connect a cylinder with a hydraulic system.

The use of hydraulic cylinders of high carrying capacity

High -loading hydraulic cylindersFind application in various industries:

- Construction:The rise and movement of heavy building materials, such as beams, slabs and concrete blocks.

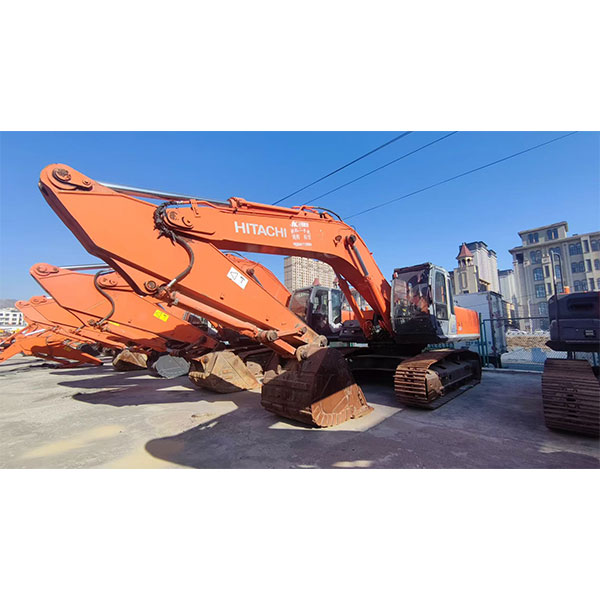

- Mining industry:Management of mining equipment, such as excavators, bulldozers and drilling rigs.

- Metallurgy:The rise and movement of ingots, rental and other metal equipment.

- Transport:Raising and lowering the bodies of dump trucks, trailers and other freight vehicles.

- Energy:Equipment management at power plants, such as turbines and generators.

Advantages of using high -loading hydraulic cylinders

UsageHydraulic cylinders of high loading capacityprovides the following advantages:

- High capacity:The ability to raise and move very heavy objects.

- Reliability:Strong design and use of quality materials provide a long service life.

- Efficiency:Transformation of hydraulic energy into mechanical with minimal losses.

- Accuracy:Providing accurate and controlled movement.

- Safety:Built -in security systems prevent overload and emergency situations.

How to choose a high -loading hydraulic cylinder

When choosingHydraulic cylinder of high loading capacityThe following factors must be taken into account:

- Carrying capacity:The maximum weight that the cylinder can safely raise or move.

- Working pressure:The maximum pressure of the hydraulic fluid that the cylinder can withstand.

- Piston stroke:The distance to which the piston can move inside the cylinder.

- Cylinder diameter:The inner diameter of the cylinder sleeve, which determines the force that the cylinder can develop at a given pressure.

- Type of installation:The method of attaching the cylinder to the equipment (flange, on eyes, etc.).

- Terms of Use:The temperature, humidity and other environmental factors that may affect the cylinder.

Technical characteristics and parameters

The most important technical characteristics that should be paid to:

- Piston diameter (mm)

- Diameter of the rod (mm)

- Piston stroke (mm)

- Maximum working pressure (MPa)

- Type of hydraulic fluid

- Cylinder material

Examples of application with data and tables

Consider examples of applicationHydraulic cylinders of high loading capacityIn different industries with specific data:

Example 1: Construction

Rise beam weighing 50 tons to a height of 10 meters. This requires a cylinder with a carrying capacity of at least 50 tons and a piston course of at least 10 meters. Company LLC Internal Mongolia Zhitsyan Construction equipment (https://www.nmgrq.ru/) may offer a wide range of hydraulic solutions for the construction industry.

Example 2: mining industry

Managing an excavator with a 10 cubic meter bucket. This requires several cylinders with various carrying capacity and piston stroke, depending on the task performed.

| Function | Carrying capacity (tons) | Piston stroke (mm) |

|---|---|---|

| Rise of an arrow | 30 | 1500 |

| Turn of the platform | 20 | 800 |

| Bucket management | 15 | 600 |

Service and repair

Regular maintenance and timely repairHydraulic cylinders of high loading capacity- The key to their long and reliable work.

The main types of service

- Checking the level of hydraulic fluid:Maintaining the optimal fluid level provides proper lubrication and cooling.

- Replacement of seals:Wondered seals can lead to leaks and a decrease in work efficiency.

- Cleaning the cylinder:Removing pollution and deposits prevents damage to internal components.

- Checking the piston rod:The rod should be straight and without damage.

Common breakdowns

- Hydraulic fluid leaks:Can be caused by wear of seals or damage to the cylinder sleeve.

- Damage to the piston rod:It can be caused by blows, overloads or corrosion.

- Piston sealing:It can be caused by pollution of the hydraulic fluid or damage to the cylinder sleeve.

Conclusion

High -loading hydraulic cylindersare indispensable components of many industrial machines and equipment. The correct choice, operation and maintenance provide their reliable and efficient work for a long time. When choosing a cylinder, it is important to take into account all the necessary technical parameters and operating conditions, as well as carry out regular maintenance to prevent breakdowns.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Cheap suppliers Hydraulic cylinder for parts

- Buy a cylinder for a lift

- Mini-excavators in China

- OEM price excavator for water resources

- Cheap main buyers Hydraulic cylinder for trucks

- cheap JCB suppliers Excavator rental Moscow

- Chinese factories for the production of hydraulic jacks

- Cheap cross pusher hydraulic cylinder of the main buyers

- Suppliers of custom -made hydraulic cylinders in China

- cheap prices for renting an excavator of a loader