Hydraulic cylinder with a metric measurement system

Hydraulic cylinder with a metric measurement system- This is a device that converts the energy of the hydraulic fluid into the mechanical operation of the linear motion. They are widely used in various industries due to their high power, reliability and accuracy. This article discusses the main types, components, areas of application and criteria for choosing hydraulic cylinders with a metric measurement system.

What is a hydraulic cylinder with a metric measurement system?

Hydraulic cylinder with a metric measurement system- This is a mechanism that uses fluid pressure to create a linear movement. In the metric system, the dimensions of the cylinder, such as the diameter of the piston and the course, are expressed in millimeters. This facilitates the design and integration with other components that also use the metric system.

The main components of the hydraulic cylinder

TypicalHydraulic cylinder with a metric measurement systemconsists of the following components:

- Gilsa (cylinder):The cylinder case, usually made of steel.

- Piston:The part moving inside the sleeve under the influence of fluid pressure.

- Stock:A metal rod connected to the piston, transmitting an effort to an external device.

- Seals:Prevent fluid leakage and ensure the tightness of the system.

- Covers:Close the ends of the cylinder, ensuring tightness and directing the liquid.

- Fitting:Used to connect hydraulic hoses.

Types of hydraulic cylinders

There are several typeshydraulic cylinders with a metric measurement system, each of which is intended for certain tasks:

Unilateral cylinders

In unilateral cylinders, the working fluid is supplied only on one side of the piston. The piston is returned to its original position by a spring, gravity or external load.

Bilateral cylinders

In bilateral cylinders, the working fluid can be supplied on both sides of the piston, which allows you to do work in both directions. They provide more accurate control and greater power.

Telescopic cylinders

Telescopic cylinders consist of several sections invested in each other. This allows you to get a large move with compact sizes in a folded state. They are often used in construction equipment and lifting mechanisms.

The use of hydraulic cylinders with a metric measurement system

Hydraulic cylinders with a metric measurement systemThey are widely used in various industries:

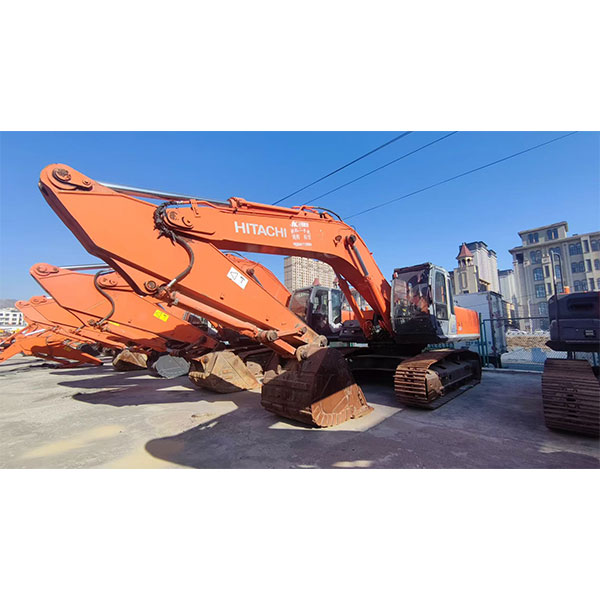

- Construction equipment:Excavators, bulldozers, loaders.

- Industrial equipment:Presses, machines, casting machines.

- Agricultural equipment:Tractors, combines, sprayers.

- Transport:Trucks, buses, lifts.

- Aviation and astronautics:Flight control systems, chassis.

How to choose a hydraulic cylinder with a metric measurement system

When choosinghydraulic cylinder with a metric measurement systemThe following factors must be taken into account:

- The necessary effort:Determine the maximum effort that the cylinder should develop.

- Traffic:Consider the required length of the piston.

- Working pressure:Select a cylinder designed for the necessary working pressure.

- Type of cylinder:Choose a suitable cylinder type depending on the task.

- Terms of Use:Consider the temperature, humidity and other environmental factors.

- Installation dimensions:Make sure that the cylinder is suitable for size and fastening method.

Advantages of using the metric system

The use of the metric system in hydraulic cylinders has a number of advantages:

- Universality:The metric system is an international standard, which simplifies the design and maintenance of equipment.

- Compatibility:It is easier to find spare parts and components that meet metric standards.

- Accuracy:The metric system provides high accuracy of measurements, which is important for precision applications.

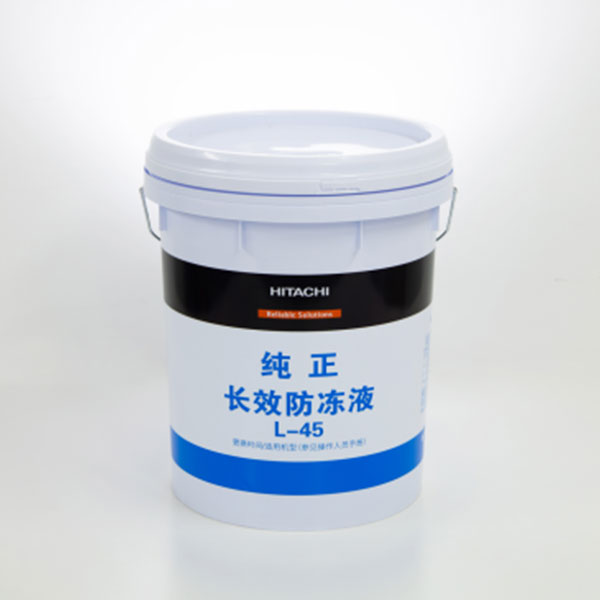

LLC Internal Mongolia Zhitsyan Construction equipment and hydraulic cylinders

Company LLC Internal Mongolia Zhitsyan Construction equipment (https://nmgrq.ru/) offers a wide rangehydraulic cylinders with a metric measurement systemFor various types of construction equipment. Our cylinders are highly reliable, durability and comply with international quality standards.

Maintenance and repair

Regular maintenance and timely repairhydraulic cylinders with a metric measurement systemallow you to extend their service life and ensure reliable operation of the equipment. It is important to monitor the condition of the seals, check the fluid level and avoid overload.

Development trends of hydraulic cylinders

ModernHydraulic cylinders with a metric measurement systemThey develop in the direction of increasing energy efficiency, weight loss and improving controllability. New materials and technologies are developed to create more compact and powerful cylinders.

Examples of technical characteristics of hydraulic cylinders

To understand the technical characteristicshydraulic cylinders with a metric measurement system, consider examples:

| Characteristic | Meaning |

|---|---|

| The diameter of the piston | 80 mm |

| The diameter of the rod | 40 mm |

| Move | 500 mm |

| Maximum pressure | 250 bar |

Conclusion

Hydraulic cylinders with a metric measurement systemare important components of many machines and equipment. Understanding their principles of work, types and characteristics allows you to correctly choose and operate these devices, providing reliable and efficient operation.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Leading Chinese buyers of sealed cylinders

- Earth excavators in China

- Suppliers of high -quality new parts of the excavator

- The price of a pile -up machine in China

- Manufacturers of hydraulic power units in China

- Chinese factories for the production of corrosion-resistant hydraulic cylinders

- Manufacturers of hydraulic cylinders of unilateral action in China

- Leading buyers of cylinders for logging equipment in China

- Cheap prices for 4 excavators

- Leading Chinese buyers of cylinders for agricultural machinery