Hydraulic electromagnetic valve

Hydraulic electromagnetic valve- This is a device that controls the fluid flow in the hydraulic system using an electromagnet. When the electric signal is supplied, the electromagnet moves the valve spool, opening or closing the channels to pass the liquid. This allows you to accurately and quickly control the operation of hydraulic equipment. Most oftenHydraulic electromagnetic valvesThey are used in construction equipment, such as excavators and loaders, in industrial machines, as well as in the automotive industry.

The main types of hydraulic electromagnetic valves

There are several main typeshydraulic electromagnetic valvesdifferent in design and principle of action:

- Direct action:In such valves, the electromagnet directly affects the spool, opening or closing the channel. They differ in a quick response, but require a more powerful electromagnet to work with high pressure.

- Pilot action:In these valves, the electromagnet controls a small pilot valve, which, in turn, controls the main spool. This allows you to use less powerful electromagnets to work with high pressure.

- Proportional:These valves allow you to smoothly adjust the fluid flow depending on the power of the electrical signal. They are used in systems requiring accurate speed control and effort.

The design and principle of operation of the hydraulic electromagnetic valve

TypicalHydraulic electromagnetic valveconsists of the following main elements:

- Corps: is made of durable material (for example, steel or cast iron) and contains channels for fluid.

- Soldier: a movable element that moves inside the case and overlaps or opens the channels.

- Electromagnet: creates a magnetic field that moves the spool.

- Spring: Returns the spool to the starting position in the absence of an electrical signal.

When the voltage is supplied to the electromagnet, a magnetic field is created, which attracts the spool. The spool moves and opens or closes the channels in the valve case, allowing the liquid to pass through it or blocking its flow. When relieved of the voltage, the spring returns the spool to its original position.

The use of hydraulic electromagnetic valves

Hydraulic electromagnetic valvesWidely used in various industries. Here are a few examples:

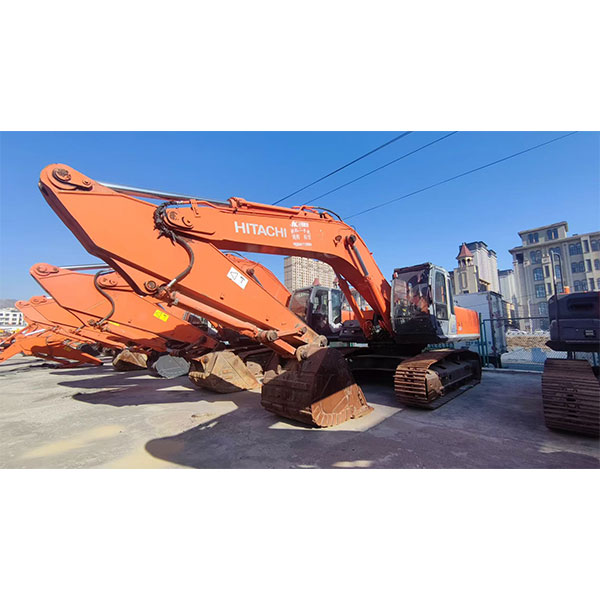

- Construction equipment:Management of hydraulic cylinders of excavators, loaders, bulldozers and other equipment.

- Industrial machines:Management of the movement of the working bodies of machine tools, such as presses, casting machines and robots.

- Automobile industry:Management of brake systems, steering control and other car hydraulic systems.

- Aviation:Management of chassis, flaps and other aircraft systems.

- Agriculture:Management of hydraulic systems of tractors, combines and other agricultural machinery.

Advantages and disadvantages of hydraulic electromagnetic valves

Hydraulic electromagnetic valveshave a number of advantages:

- Fast response:Provide the rapid switching of fluid flow.

- Accurate control:Allow you to accurately control the operation of the hydraulic system.

- Reliability:They have a strong design and a long service life.

- Convenience of management:Easily controlled using electrical signals.

However, they have some shortcomings:

- Pollution sensitivity:They require clean working fluid for reliable operation.

- Energy consumption:The electromagnet consumes electricity during operation.

- Noise:They can create noise when switching.

Selection of hydraulic electromagnetic valve

When choosinghydraulic electromagnetic valveThe following factors must be taken into account:

- Working pressure:The maximum pressure that the valve can withstand.

- Fluid consumption:The maximum volume of fluid that can pass through the valve per unit of time.

- Valve type:Direct action, pilot action or proportional.

- Power voltage:The voltage required for the operation of the electromagnet.

- Type of working fluid:Valve compatibility with the working fluid used.

- Terms of Use:Temperature, humidity and other environmental factors.

It is recommended to contact specialists such as the companyLLC Internal Mongolia Zhitsyan Construction equipment, to obtain consultation and selection of optimalhydraulic electromagnetic valveFor your specific needs.

Maintenance of hydraulic electromagnetic valves

Regular maintenance is the key to long and reliable workhydraulic electromagnetic valve. The main services for maintenance include:

- Regular check:Visual inspection of the valve for leaks, damage and wear.

- Cleaning:Cleaning the valve of pollution and deposits.

- Filter replacement:Regular replacement of filters in the hydraulic system to prevent pollution from the valve.

- Checking electrical connections:Checking and lifting electrical connections to ensure reliable contact.

- Replacement of seals:Replacement of seals when leaks or signs of wear.

Examples of technical characteristics of hydraulic electromagnetic valves

For example, we give a table with the technical characteristics of several common modelshydraulic electromagnetic valves:

| Model | Working pressure (bar) | Consumption (l/min) | Stress (c) |

|---|---|---|---|

| 4WE6D-6X/OFEG24N9K4 | 315 | 80 | 24 DC |

| 4WE10D-4X/CW230N9K4 | 350 | 120 | 230 AC |

| DHI-0631/2/A | 350 | 60 | 24 DC |

The data is presented for familiarization and may differ depending on the manufacturer and the model.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Chinese factories for the production of high -pressure hydraulic pumps

- Cheap sealing cylinder factory

- High quality exports of used excavators prices

- Cheap suppliers Hydraulic cylinder press

- Cheap woods Graiff cylinder factory

- OEM suppliers Earth excavator

- Sale of imported excavators

- Cheap long stroke hydraulic cylinder of the main buyers

- Hydraulic cylinder of the rotational cultivator

- Prices for spare parts for hitachi chassis in China