Case for the maintenance of the excavator ZX360-3

On August 16, 2025, at the ZX360-3 excavator, in the mining area of the city of UAI, when working with a high load, a slip of the bucket hydraulic cylinder occurred. The measurements showed that the hydraulic cylinder dropped 20 mm in 3 minutes 14 seconds and 38 mm in 5 minutes, which significantly exceeds the standard requirement of not more than 20 mm in 5 minutes.

Pre -service staff followed standard procedures: they replaced the entire set of oil seals and checked the internal wall of the hydraulic cylinder for wear, but the problem did not disappear. After the standard repair did not help to solve the problem, the equipment was transferred to our company for in -depth diagnostics.

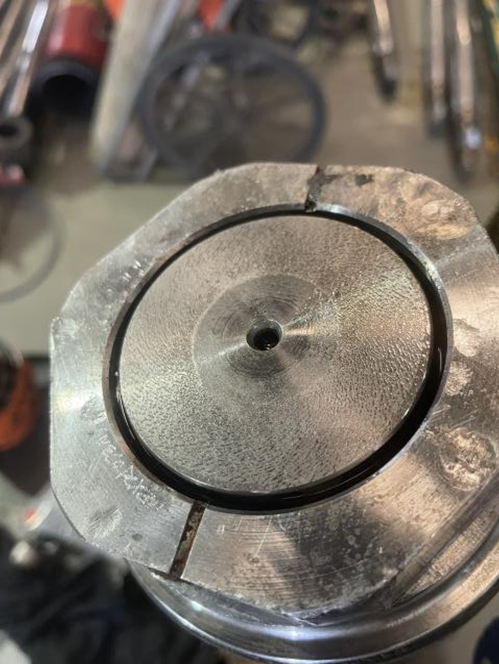

Our technical team used specialized equipment for testing the hydraulic system to test the hydraulic cylinder for tightness and under pressure. High -precision devices showed that, despite the serviceability of the oil seals, an abnormal leak was observed between the large and small cavities of the hydraulic cylinder. Further disassembly and inspection showed that the gap between the main nut of the cylinder and the threaded bolt exceeded the permissible range, which led to the failure of the hydraulic seal.

To solve this problem, our technical team used a specialized tool for reconstruction of the cylinder, replaced the main nut node with a standard gap and restored overall tightness in accordance with technical requirements. Post -embassy tests showed that the cylinder withstood a dent of only 12 mm in 5 minutes under a large load, which fully complies with the technical standards of equipment.

This repair demonstrates that to eliminate malfunctions of the hydraulic system is not enough for a planned replacement of seals; A comprehensive analysis of its design is needed. Using our specialized diagnostic equipment for hydraulic systems and extensive repair experience, we can accurately determine these structural faults and offer our customers really effective solutions.