Chinese suppliers The principle of a hydraulic cylinder

Chinese suppliers The principle of a hydraulic cylinderIt is based on the use of liquid under pressure to create linear motion. The hydraulic system converts the energy of fluid pressure into mechanical energy, which allows you to perform various tasks that require significant efforts. We will figure out the main components and the principle of the action of hydraulic cylinders.

The main components of the hydraulic cylinder

The hydraulic cylinder consists of several key components:

- Cylinder sleeve:Strong body withstanding high pressure.

- Piston:A part that moves inside the sleeve and transforming the pressure of the fluid into linear motion.

- Stock:It is connected to the piston and transfers an effort to external equipment.

- Seals:Provide the tightness between the moving parts of the cylinder, preventing fluid leakage.

- Ports:Holes for the supply and removal of hydraulic fluid.

The principle of operation of the hydraulic cylinder

The work of the hydraulic cylinder is based on the Pascal law, which states that the pressure attached to the vicious liquid is transmitted evenly to all directions. The process of work can be divided into the following stages:

The supply of hydraulic fluid

The hydraulic fluid under pressure is supplied to the cylinder sleeve through one of the ports. The pressure of the fluid affects the piston, creating strength.

Creating effort

The force created by the pressure of the liquid pushes the piston inside the sleeve. The value of force depends on the area of the piston and fluid pressure:F = p * awhere F is strength, p is pressure, a is the piston area. It is important to consider thatChinese suppliers The principle of a hydraulic cylinderThey can offer cylinders with various diameters of the pistons and, accordingly, with different efforts.

The movement of the rod

The piston, moving inside the sleeve, moves the rod. The rod transfers an effort to external equipment, performing the necessary work, whether it is lifting the cargo, moving the mechanism or compression of the material.

Return to its original position

To return the cylinder to its original position, the hydraulic fluid is supplied through another port, forcing the piston to move in the opposite direction. In unilateral cylinders, return is carried out using a spring or under the influence of gravity.

Types of hydraulic cylinders

There are several types of hydraulic cylinders that differ in design and the principle of action:

- Unilateral cylinders:They have one port for supplying fluids and do work in only one direction. Return to the starting position is carried out by a spring or under the influence of gravity.

- Bilateral cylinders:They have two ports for supplying fluids and do work in both directions. They provide more accurate control over the movement of the rod.

- Telescopic cylinders:Consist of several sections invested one into the other. They allow you to get a large stroke of the rod with compact size of the cylinder.

The use of hydraulic cylinders

Hydraulic cylinders are widely used in various industries and technology, due to their high power, reliability and accuracy of control:

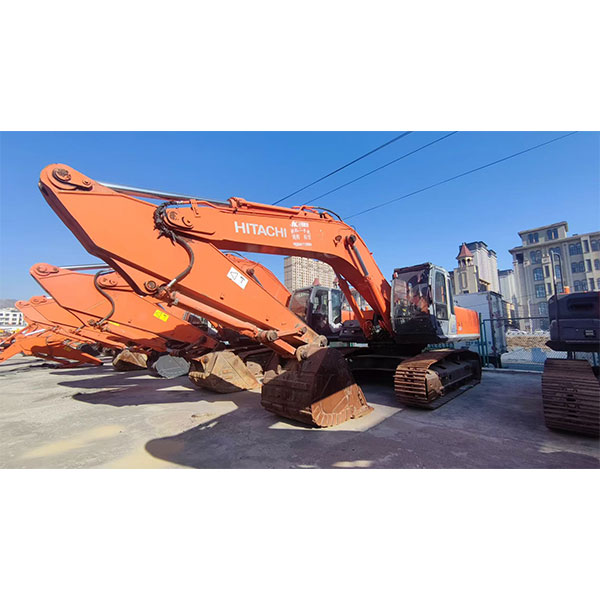

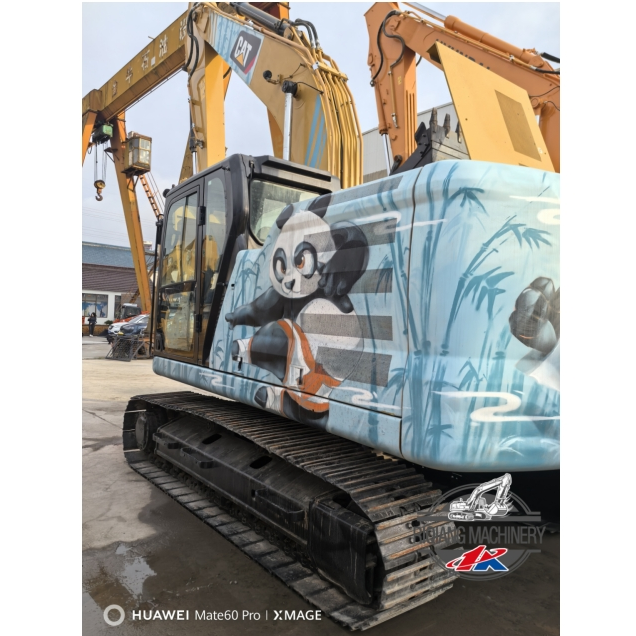

- Construction equipment:Excavators, bulldozers, taps.

- Agricultural equipment:Tractors, combines, loaders.

- Metallurgy:Presses, rolling camps.

- Automobile industry:Lifts, brake systems.

- Aviation:Chassis, steering systems.

The choice of a hydraulic cylinder

When choosing a hydraulic cylinder, the following parameters must be taken into account:

- Working pressure:The maximum pressure that the cylinder can withstand.

- Piston diameter:Determines the force that can create a cylinder.

- Rod move:The distance that the rod can move to.

- Type of cylinder:One -sided, bilateral or telescopic.

- Introductory dimensions:The sizes of ports and fasteners.

It is recommended to contact verifiedChinese suppliers, such as LLC Inner Mongolia Zhitsyan Construction equipment (https://www.nmgrq.ru/) to get high -quality equipment and professional advice.

Advantages and disadvantages of hydraulic cylinders

| Advantages | Flaws |

|---|---|

| High power and carrying capacity | The possibility of hydraulic fluid leaks |

| Smooth and accurate control | Sensitivity to fluid pollution |

| Reliability and durability with proper operation | The need for regular maintenance |

Typical problems and their solutions

Like any equipment, hydraulic cylinders may encounter certain problems. Here are some of them and ways to solve them:

- Fluid leak:Check and replace the seals. Make sure that there is no damage to the cylinder and a rod.

- Slow movement of the piston:Check the level of hydraulic fluid, the condition of the pump and filters.

- Jerks when moving:Check the presence of air in the system and delete it. Make sure the valves are working.

- Extraneous noises:Check the condition of bearings and other mechanical components.

Service and care

To ensure reliable and durable operation of hydraulic cylinders, regular maintenance must be carried out:

- Regular replacement of hydraulic fluid:To maintain its purity and prevent components wear.

- Checking and replacing filters:To prevent pollution from getting into the system.

- Lubrication of mobile parts:To reduce friction and wear.

- Visual inspection:To identify leaks, damage and other problems.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Cheap staircase truck Hydraulic cylinder of manufacturers

- Chinese suppliers of seals of the piston rod

- Chinese manufacturers of the internal structure of the hydraulic cylinder

- The price of a construction excavator in China

- Cheap double -acting hydraulic cylinder of suppliers

- Cheap main buyers repair of hydraulic cylinders

- Komatsu excavator prices from China

- The cylinder of the garbage truck

- Suppliers are cheap excavator

- Hydraulic cylinder with double rod to order