Non -standard hydraulic cylinder

Non -standard hydraulic cylinder- This is a hydraulic cylinder developed and made taking into account specific requirements and operating conditions that cannot be satisfied with standard models. It may differ from standard, design, materials, working characteristics and other parameters.

What is a non -standard hydraulic cylinder?

Non -standard hydraulic cylinder- This is an individually designed hydraulic cylinder created for specific tasks and conditions when standard models are not suitable. This may be due to unique requirements for the size, loads, working environments or special installation conditions.

The main differences from standard models

The main difference between a non -standard cylinder is its uniqueness. It is developed for a specific task, while standard models are serial products designed for a wide range of applications.Non -standard hydraulic cylindersThey may have unique design features, materials and parameters optimized for specific working conditions.

When is a non -standard hydraulic cylinder needed?

The need fornon -standard hydraulic cylinderIt arises in cases where standard models cannot provide the required characteristics or functionality. Here are a few common situations:

- Limited space:When the dimensions of the equipment are very limited, and the standard cylinder simply does not fit.

- Specific loads:If the cylinder must withstand extreme loads, temperature or pressure.

- Aggressive environment:When the cylinder works in conditions of high humidity, dustiness, under the influence of chemicals or other aggressive factors.

- Unique installation requirements:If non -standard mounts or arrangement of ports are required.

- High accuracy and reliability:In cases where the maximum positioning accuracy or non -failure work in critically important systems is required.

Design and manufacture of non -standard hydraulic cylinders

Design and manufacturing processnon -standard hydraulic cylinders- A difficult and responsible task requiring high qualifications and experience. It includes several stages:

Stage 1: Analysis of requirements and development of technical specifications

At this stage, it is necessary to carefully study the requirements of the customer, operating conditions of the cylinder, load, working environment and other factors. Based on these data, a technical task is developed, in which all the parameters and characteristics of the future cylinder are clearly defined.

Stage 2: Design Development

At this stage, the designers develop a 3D model of the cylinder, choose materials, calculate the strength and reliability of the structure. It is important to consider all the nuances, such as the type of sealing, the method of attachment, the location of the ports and other details.

Stage 3: Making parts and assembly

After the completion of the design development, the process of making parts of the cylinder begins. This may include turning, milling, welding and other types of work. Then the details are collected in the finished cylinder, which undergoes quality control and testing.

Stage 4: Testing and Quality Control

ReadyNon -standard hydraulic cylinderHe is subjected to a series of tests to make sure of its compliance with the technical specifications and safety requirements. Testing may include testing for strength, tightness, performance under load and other parameters.

Use of non -standard hydraulic cylinders

Non -standard hydraulic cylindersThe application is found in various industries, where solutions adapted to specific conditions are required. Several examples:

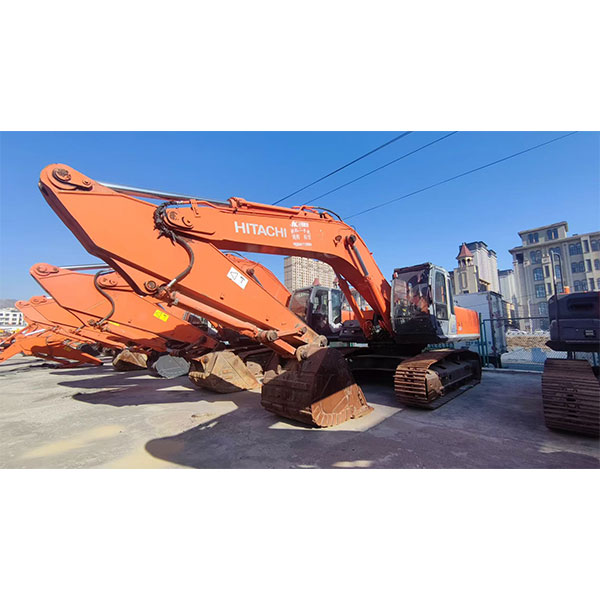

- Construction equipment:For excavators, cranes, bulldozers and other equipment working in difficult conditions. LLC Internal Mongolia Zhitsyan Construction equipment (https://www.nmgrq.ru/) supplies a wide range of hydraulic solutions for the construction industry, includingNon -standard hydraulic cylinders.

- Metallurgy:For rolling mills, presses, guillotine and other equipment working with high loads and temperatures.

- Mining industry:For drilling rigs, excavators, dump trucks and other equipment operating in conditions of increased dusting and humidity.

- Oil and gas industry:For drilling platforms, pumping stations, pipelines and other equipment operating in aggressive media and extreme climatic conditions.

- Aviation and Space Industry:For a chassis of aircraft, missile control systems and other equipment, where high reliability and accuracy are required.

How to choose a manufacturer of non -standard hydraulic cylinders?

The choice of a reliable manufacturernon -standard hydraulic cylinders- An important step on which the durability and effectiveness of your equipment depends. When choosing, you should pay attention to the following factors:

- Experience and qualifications:Make sure that the manufacturer has experience in the development and manufacture of non -standard cylinders for your industry.

- Production capabilities:The manufacturer must have the necessary equipment and technologies for the manufacture of cylinders with the required parameters and characteristics.

- Quality control:The manufacturer must have a quality control system that guarantees the compliance of the cylinders with the requirements of the technical specifications and security standards.

- Reputation and reviews:Learn the reviews of other customers about the manufacturer to make sure his reliability and professionalism.

- Warranty and service:Find out what guarantees the manufacturer provides for its products and what service he offers.

An example of a non -standard hydraulic cylinder

Consider an examplenon -standard hydraulic cylinderdeveloped for an excavator working in the Far North. Standard cylinders in such conditions quickly fail due to low temperatures and high humidity.

For this excavator, a cylinder was developed with the following features:

- Material:A special steel was used, resistant to low temperatures and corrosion.

- Seals:Frost -resistant seals are installed, providing tightness at extreme temperatures.

- Coating:The cylinder is covered with a special anti -corrosion composition that protects it from moisture and salt.

- Heating:Electric heating is built into the cylinder design, providing its performance at low temperatures.

Thanks to these features,Non -standard hydraulic cylindersignificantly increased the reliability and durability of an excavator working in harsh conditions.

Advantages of using non -standard hydraulic cylinders

Usagenon -standard hydraulic cylindersgives a number of advantages compared to standard models:

- Optimization for specific tasks:The cylinder is developed taking into account all the requirements and operating conditions, which allows you to achieve maximum efficiency and reliability.

- Increase in the service life of equipment:Thanks to the use of special materials and structural solutions,Non -standard hydraulic cylindersThey last longer than standard ones.

- Reducing the costs of maintenance and repair:The reliability and durability of the cylinders can reduce the costs of their maintenance and repair.

- Safety increase:The use of cylinders developed taking into account security requirements reduces the risk of accidents and accidents.

Conclusion

Non -standard hydraulic cylinders- This is the best solution for cases when standard models are not suitable. They allow you to optimize the operation of equipment, increase its service life and reduce service costs. When choosing a manufacturer of non -standard cylinders, it is important to take into account his experience, production capabilities, quality control system and reputation.

If you need itNon -standard hydraulic cylinder, contact the specialists of LLC International Mongolia Zhitsyan Construction equipment at the addresshttps://www.nmgrq.ru/. They will help you develop and make a cylinder that will perfectly meet your requirements.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Wheel excavator

- High quality price Full used excavator

- Leading buyers of China high pressure Durable hydraulic pumps

- Trimmer fence hydraulic cylinder suppliers in China

- Chinese suppliers of high -pressure hydraulic pumps

- Cheap price of a hydraulic cylinder for the press

- Chinese factories for the production of 24-volt engines

- Cheap hydraulic piston of the main buyers

- Cylinders for agricultural machinery in China

- Cheap hydraulic cylinder 30 factories