Galled cylinder

Galchasted cylinders- These are indispensable components in various industries and construction, due to its high resistance to corrosion and durability. They are used in hydraulic systems, pneumatic equipment, as structural elements and in many other areas. In this article, we will consider in detail the characteristics, application and features of the choicegalvanized cylindersTo help you make the right choice for your tasks.

What's happenedGalled cylinder?

Galled cylinder- This is a cylindrical part made of steel and covered with a layer of zinc. This process, known as galvanization, provides protection from corrosion, significantly prolonging the service life of the product. Zinc acts as a barrier, preventing the contact of steel with moisture and oxygen, and also provides cathode protection in which zinc donates itself, protecting steel even if the coating is damaged.

Typesgalvanized cylinders

There are several typesgalvanized cylindersdiffering in the method of applying zinc coating:

- Hot zing:Steel is immersed in molten zinc. This method provides a thick and strong coating that is ideal for external use and aggressive environments.

- Electrolytic zinclovania:Zinc is applied to steel using electrolysis. The coating is thinner and smooth than with hot zincing.

- Thermodyffusion zincThe product is heated in an environment containing zinc, as a result of which zinc diffuses into a surface layer of steel.

Advantages of usegalvanized cylinders

Usagegalvanized cylindersprovides a number of advantages:

- Corrosion resistance:The main advantage is protection against rust and corrosion, which increases the service life of the product.

- Durability:The zinc coating provides durability even in difficult operating conditions.

- Economics:Reducing the costs of maintenance and replacement due to the long service life.

- Universality:Suitable for a wide range of applications in various industries.

Applicationgalvanized cylinders

Galchasted cylindersThey are widely used in various industries:

- Hydraulic systems:Used as cases of hydraulic cylinders and other components.

- Pneumatic equipment:They are used in pneumatic cylinders and systems.

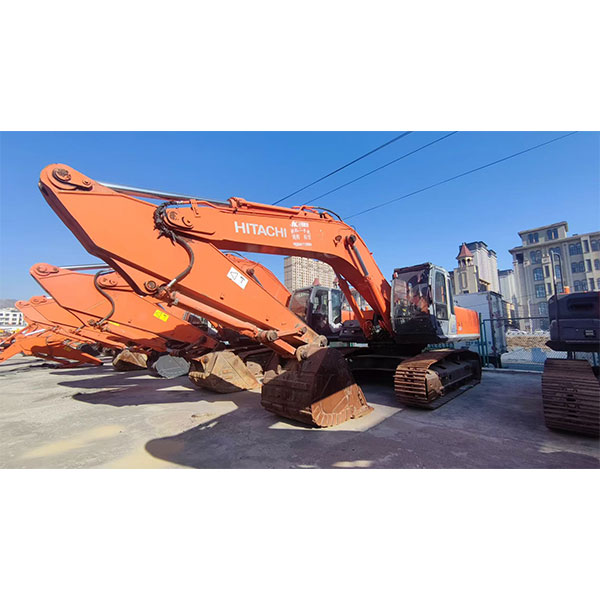

- Construction:Used as elements of structures, fences, supports and other building elements. LLC Internal Mongolia Zhitsyan Construction equipment (https://www.nmgrq.ru/) offers a wide range of construction equipment, where they are often usedGalchasted cylinders.

- Automobile industry:Used as components of brake systems, shock absorbers and other components.

- Agriculture:They are used in agricultural equipment and equipment.

How to chooseGalled cylinder?

When choosinggalvanized cylinderSeveral factors must be taken into account:

- Material:Choose steel that meets the requirements of your project.

- Type of zinc coating:Consider the operating conditions and the necessary degree of corrosion protection. Hot zing is usually recommended for external use and aggressive environments.

- Dimensions and characteristics:Make sure that the dimensions and characteristics of the cylinder meet the requirements of your equipment or design.

- Manufacturer:Choose reliable manufacturers guaranteeing product quality.

Factors affecting service lifegalvanized cylinders

The service lifegalvanized cylindersDepends on several factors:

- The thickness of the zinc coating:The thicker the coating, the longer the service life.

- Terms of Use:The impact of aggressive media, such as salt water or industrial chemicals, can reduce the life of the service.

- Coating quality quality:Uniform and dense coating provides better protection.

- Service:Regular cleaning and inspection may extend the service life.

Technical characteristicsgalvanized cylinders

Technical characteristicsgalvanized cylindersvary depending on the manufacturer and the area of application. Important parameters are:

- Diameter:The internal and external diameters of the cylinder.

- Length:The total length of the cylinder.

- Wall thickness:The thickness of the cylinder wall, which affects strength and resistance to pressure.

- Tensile strength:The maximum pressure that can withstand the cylinder without destruction.

- The thickness of the zinc coating:It is measured in micron (MKM) and determines the degree of protection against corrosion.

Approximate values of zinc coating for various methods:

| Galing method | Coating thickness (MKM) |

|---|---|

| Hot zing | 45-120 |

| Electrolytic zing | 5-25 |

| Thermodyfusion zinc | 15-50 |

Maintenance and care forgalvanized cylinders

Proper maintenance and care will help extend the service lifegalvanized cylinders:

- Regular cleaning:Remove dirt, dust and other pollution from the surface of the cylinder.

- Inspection:Periodically check the coating for damage, such as scratches, chips and cracks.

- Repair:If damage to the coating is detected, perform repairs using special means to restore the zinc layer.

- Protection against aggressive environments:Avoid contact with aggressive chemicals and salt water.

Conclusion

Galchasted cylinders- These are reliable and durable components that provide protection against corrosion and increase the service life of equipment and structures. With the right choice and maintenance, they can last many years, reducing the cost of maintenance and replacement. The company LLC Internal Mongolia Zhitsyan construction equipment is pleased to offer you a wide selection of construction equipment and components, including andGalchasted cylinders. For more information, please visit our site:https://www.nmgrq.ru/.

This article is informational. To obtain accurate information about technical characteristics and applicationgalvanized cylindersIt is recommended to contact manufacturers and suppliers.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- The hydraulic cylinder of the trimmer for the fence

- Cheap mechanical parts hydraulic cylinder price

- Buy a hydraulic hammer: price

- OEMHITACHI filter suppliers

- Chinese suppliers buy Japanese excavators

- Cheap price hydraulic cylinder 30

- Suppliers of Hitachi wheel excavators in China

- Chinese manufacturers of hydraulic cylinders for the rear doors of trucks

- Chinese manufacturers of hydraulic pistons

- Cheap manufacturers of stable performance hydraulic cylinder