Manufacturers the principle of a hydraulic cylinder in China

Hydraulic cylinders are mechanisms that convert the hydraulic energy of the liquid into mechanical energy to create linear motion. China is one of the largest manufacturers of hydraulic cylinders in the world, offering a wide range of products for various industries, from construction and mining to agriculture and production. The choice of a suitable supplier and an understanding of the principles of the operation of these devices are critical to ensure the reliability and efficiency of equipment.

The main manufacturershydraulic cylindersIn China

Chinese markethydraulic cylindersIt is represented by many companies, both large and small. It is important to choose manufacturers who have a good reputation and offer products that meet international quality standards. For example, the company LLC Internal Mongolia Zhitsyan Construction equipment (https://www.nmgrq.ru/) specializes in the supply of construction equipment and components, including high -qualityHydraulic cylinders.

How to choose a suitable manufacturer?

When choosing a manufacturerhydraulic cylindersThe following factors must be taken into account:

- Reputation and experience:Evaluate the company's experience in the market and customer reviews.

- Product quality:Request quality certificates and test results.

- Technical characteristics:Make sure that the products meet your requirements for pressure, go, diameter and other parameters.

- Price:Compare the prices of different manufacturers, given the ratio of price and quality.

- Service service:Learn about the availability of service support and spare parts.

The principle of workhydraulic cylinder

Hydraulic cylinder- This is a device that converts the energy of the working fluid into the mechanical energy of the progressive movement. It consists of a case, a piston, a rod and seals. The principle of operation is based on the law of Pascal, which states that the pressure attached to the liquid in a closed system is transmitted equally in all directions.

The main components and their functions

- Cylinder case:Provides tightness and protection of internal components.

- Piston:It divides the cylinder into two chambers and moves under the influence of fluid pressure.

- Stock:Passes the force from the piston to the external mechanism.

- Seals:Provide tightness between the moving parts of the cylinder and prevent fluid leakage.

Stages of workhydraulic cylinder

- The working fluid under pressure enters one of the cylinder chambers.

- The pressure of the fluid affects the piston, forcing it to move.

- The movement of the piston is transmitted through the rod to the external mechanism.

- The liquid from another cylinder chamber merges into the tank.

Typeshydraulic cylinders

There are several main typeshydraulic cylindersdiffering in design and principle of action:

- Unilateral cylinders:One direction movement is carried out under the action of fluid pressure, and a return to its original position is carried out under the influence of a spring or gravity.

- Bilateral cylinders:Movement in both sides is carried out under the action of the pressure of the liquid supplied to different cells of the cylinder.

- Telescopic cylinders:They consist of several cylinders embedded in each other, which allows you to increase the cylinder stroke while maintaining compact sizes.

Applicationhydraulic cylinders

Hydraulic cylinderswidely used in various industries, including:

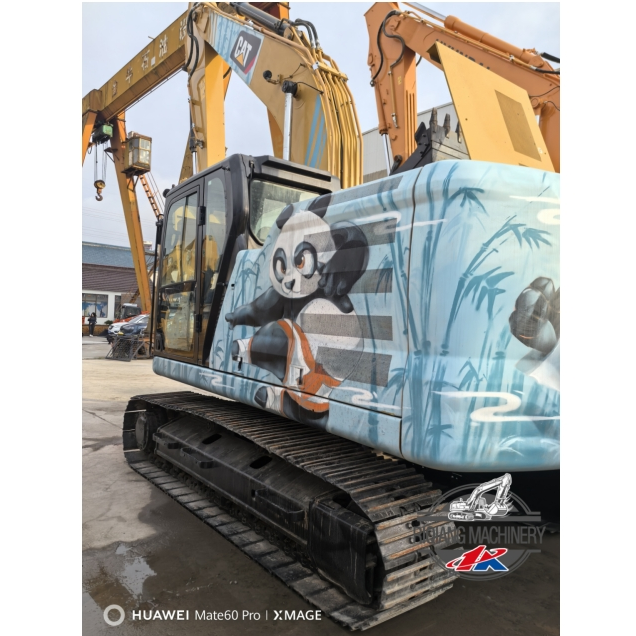

- Construction:Excavators, bulldozers, cranes and other construction equipment.

- Mining industry:Board installations, crushers and other mining equipment.

- Agriculture:Tractors, combines and other agricultural equipment.

- Production:Machines, presses and other production equipment.

Technical characteristicshydraulic cylinders

When choosinghydraulic cylinderIt is necessary to take into account its technical characteristics, such as:

- Working pressure:The maximum pressure that can withstand the cylinder.

- Piston diameter:Determines the force that can develop the cylinder.

- Piston stroke:Determines the distance to which the piston can move.

- Type of connection:Determines the method of connecting the cylinder to the hydraulic system.

Comparison table of technical characteristicshydraulic cylindersvarious manufacturers

| Manufacturer | Working pressure (MPa) | Piston diameter (mm) | Piston stroke (mm) |

|---|---|---|---|

| Manufacturer a | 25 | 80 | 500 |

| Manufacturer b | 30 | 100 | 800 |

| LLC Internal Mongolia Zhitsyan Construction equipment | Up to 35 | From 50 to 200 | On request |

*The data are given as an example and may differ depending on the cylinder model. To get accurate information, contact the manufacturers.

Service and repairhydraulic cylinders

To ensure reliable and durable workhydraulic cylindersIt is necessary to regularly conduct their maintenance, which includes:

- Check the level and condition of the working fluid.

- Replacing filters.

- Checking the tightness of the compounds.

- Lubrication of mobile parts.

In case of malfunctions, it is necessary to carry out repairs in a timely mannerhydraulic cylinders. Repair may include replacing seals, pistons, rods or other components.

Conclusion

Choicehydraulic cylinder- A responsible task requiring the accounting of many factors. It is important to choose a reliable manufacturer, such as LLC Inner Mongolia Zhitsyan Construction equipment, and take into account the technical characteristics of the cylinder, as well as the conditions of its operation. Proper maintenance and timely repair will help to ensure reliable and durable workhydraulic cylinder.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Hydraulic hose

- Leading Chinese buyers of hydraulic cylinders assembly

- Prices for hydraulic cylinders for mining equipment in China

- Prices for buying a caterpillar excavator in China

- Cheap bastard cylinder of factories

- Chinese manufacturers of hydraulic power plants

- Manufacturers of hydraulic cylinders of loaders in China

- Cheap fence trimmer Hydraulic cylinder of suppliers

- Chinese suppliers of hydraulic pistons

- The original model of the excavator