Standard hydraulic cylinder

Standard hydraulic cylinder- This is a mechanical device used to convert hydraulic energy into linear motion and strength. It consists of a cylindrical case, piston, rod and seals, and is an important component in many industrial and mobile applications. The choice of the correct cylinder depends on many factors, including the required strength, move, working pressure and the environment.

What's happenedStandard hydraulic cylinder?

Standard hydraulic cylinder- This is a hydraulic cylinder produced in accordance with generally accepted standards of size and technical characteristics. This makes them interchangeable and facilitates their search and replacement. LLC Internal Mongolia Zhitsyan Construction equipment (nmgrq.ru) offers a wide rangestandard hydraulic cylinderscorresponding to the highest quality standards.

The main components

TypicalStandard hydraulic cylinderconsists of the following main components:

- Cylindrical pipe:Provides the case for the piston and hydraulic fluid.

- Piston:Moves inside the cylinder, converting hydraulic energy into mechanical.

- Stock:It is connected to the piston and transfers linear motion and strength to the external load.

- Seals:Prevent the leakage of hydraulic fluid and provide smooth movement of the piston.

- Covers:Close the ends of the cylinder and provide fastening for the rod and hydraulic compounds.

Typesstandard hydraulic cylinders

There are several main typesstandard hydraulic cylinders, each of which is intended for specific applications:

- One -way action:They make an effort in only one direction, and the return to the starting position is carried out by a spring or external force.

- Bilateral action:They make an effort in both directions, which provides greater control and versatility.

- Telescopic:They have several steps, which allows you to achieve a large stroke with compact sizes.

How to choose the right oneStandard hydraulic cylinder

The choice is suitablestandard hydraulic cylinderRequires a thorough consideration of several factors. Here are some key points that should be taken into account:

Calculation of the required force

The first step is to determine the required force to complete a specific task. It depends on the weight or load that needs to be moved, and the acceleration with which this must be done. The formula for calculating power is as follows:

Strength (f) = pressure (p) x Piston area (a)

Make sure that the selected cylinder can withstand maximum pressure in your hydraulic system.

Definition of the required move

The course is the distance to which the cylinder rod is necessary. Make sure that the selected cylinder has a sufficient move for your application.

Selection of suitable working pressure

The working pressure of the hydraulic system should correspond to the nominal pressure of the cylinder. Exceeding nominal pressure can lead to damage to the cylinder and unsafe operation.

Accounting of environmental conditions

Environmental conditions, such as temperature, humidity and exposure to chemicals, can affect the performance and durability of the cylinder. Choose cylinders with appropriate seals and materials for specific conditions.

Applicationstandard hydraulic cylinders

Standard hydraulic cylindersused in a wide range of applications, including:

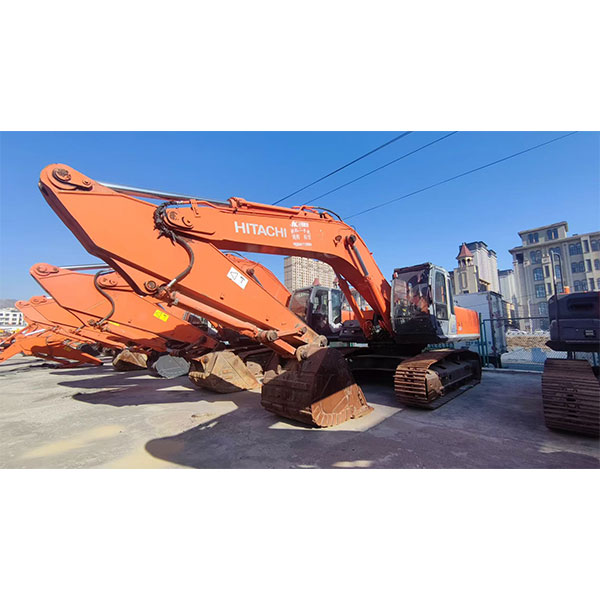

- Construction equipment:Excavators, bulldozers, loaders.

- Industrial equipment:Presses, cast cars, machines.

- Agricultural equipment:Tractors, combines, plows.

- Transport:Hydraulic lifts, brake systems.

Advantages of usestandard hydraulic cylinders

Usagestandard hydraulic cylindershas several advantages, including:

- Interchangeability:The ease of search and replacement.

- Accessibility:A wide selection of models and sizes.

- Economics:Usually cheaper than non -standard cylinders.

- Reliability:Designed and manufactured in accordance with generally accepted standards.

Care and maintenancestandard hydraulic cylinders

Proper care and maintenance are necessary to ensure long and reliable workstandard hydraulic cylinder. Here are some tips:

- Regularly check the level of hydraulic fluid and add it if necessary.

- Lubricate the cylinder rod to prevent corrosion and wear.

- Check the seals for the presence of leaks and replace them if necessary.

- Clean the cylinder of dirt and garbage.

Table of comparison of characteristicsstandard hydraulic cylinders

| Characteristic | One -sided action | Bilateral action |

|---|---|---|

| The direction of power | One | Two |

| Return | Spring/external force | Hydraulic |

| Control | Limited | More accurate |

| Application | Rise, pressing | Movement, positioning |

Where to buyStandard hydraulic cylinder

LLC Internal Mongolia Zhitsyan Construction equipment (nmgrq.ru) offers a wide selectionstandard hydraulic cylindershigh quality. Here you will find cylinders of various sizes and technical characteristics that meet the needs of any application. Contact us today to learn more about our products and get a consultation on choosing a suitable cylinder.

Conclusion

Standard hydraulic cylindersare important components in many industrial and mobile applications. The choice of the correct cylinder requires a thorough consideration of several factors, including the required strength, course, working pressure and environmental conditions. Following the advice presented in this article, you can chooseStandard hydraulic cylinder, which will meet your needs and provide reliable and durable work.

The information presented in this article is intended only for information purposes and should not be considered as a professional consultation. Always consult with a specialist when choosing and using hydraulic equipment.

Data on the characteristics of the cylinders are taken from the sites of manufacturers of hydraulic equipment.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Cheap bucket truck Hydraulic cylinder of manufacturers

- Welding cylinder

- ISUZU engine price

- Cheap cross pusher hydraulic cylinder of manufacturers

- Chinese manufacturers of hydraulic cylinders with a transverse pusher

- Cylinder for agricultural machinery

- Spare parts for excavators from China

- Chinese factories for the sale of professional hydraulic cylinders

- Rent of a wheel excavator price in China

- Cheap unilateral acting hydraulic cylinder of the main buyers