Prices for a hydraulic cylinder for a rotary milling cutter in China

Search for optimalhydraulic cylinder for rotary millingBy profitableprice in China- An important task for enterprises involved in construction, mining industry and other industries. The cost depends on many factors, including the technical characteristics, manufacturer and the volume of the order. This article provides a detailed market analysis, considers the main factors affectingPricesAnd gives recommendations for the choice of a reliable supplier.

What is a hydraulic cylinder for a rotor mill and where is it used?

Hydraulic cylinder for rotary milling- This is a key component that provides the necessary force for rotation and positioning of the cutter. It converts the energy of the hydraulic fluid into a mechanical fluid, allowing the rotor milling to effectively destroy and grind various materials.

Rotor mills, in turn, are widely used in:

- Construction: for digging trenches, preparing foundations, demolition of buildings and structures.

- Mining industry: for mining, fragmentation of ore and preparation of illnesses.

- Road construction: for stabilization of soil, milling asphalt and concrete.

- Tunneling: for passing tunnels and creating underground communications.

Factors affectingPrices for hydraulic cylinders for rotary mills in China

OnPrices for hydraulic cylinders for rotary mills, producedIn China, many factors affect:

Technical characteristics

The key parameters of the cylinder, such as the diameter of the piston, the stroke of the rod, working pressure and effort, directly affect its cost. More powerful and reliable cylinders with improved characteristics are usually more expensive. LLC Internal Mongolia Zhitsyan Construction equipment offers a wide selection of hydraulic cylinders that meet various technical requirements.

Materials and quality of manufacture

The materials used (high -strength steel, sealing elements) and the quality of manufacture determine the durability and reliability of the cylinder. Cylinders made of high -quality materials using modern technologies are usually more expensive, but they also serve longer, reducing the total cost of ownership.

Manufacturer and brand

Famous manufacturers with a good reputation often offer more expensive cylinders than less well -known companies. However, the choice of a proven brand can guarantee high quality, reliability and accessibility of spare parts. In the marketChinaA wide range of manufacturers is presentedhydraulic cylinders, from large corporations to small enterprises.

The volume of the order

When ordering large partieshydraulic cylinders, manufacturers usually provide discounts, which allows you to reduce the cost of a unit of production. Therefore, if you need a large number of cylinders, it is advisable to consider the possibility of wholesale purchase.

Equipment and additional options

The presence of additional options, such as position sensors, safety valves, special coatings, can increase the cost of the cylinder. Before the order, it is necessary to determine which options are necessary for your specific task in order to avoid overpayment for unnecessary functions.

Currency exchange rate

BecausePrices for hydraulic cylindersOften indicated in US dollars, yuan fluctuations in the dollar can affect the final cost of products. This factor must be taken into account when planning the budget and concluding contracts.

Logistics and customs duties

Delivery cost fromChinaand customs duties also affect the total costhydraulic cylinder. It is necessary to take into account these costs when comparing the proposals of various suppliers.

Comparisonprices for hydraulic cylinders for rotary mills in China

We give approximate onesPrices for hydraulic cylinders for rotary mills in ChinaDepending on the technical characteristics:

| Characteristics | Approximate price (USD) |

|---|---|

| Diameter of the piston: 50 mm, stroke of the rod: 300 mm, working pressure: 25 MPa | |

| Piston diameter: 80 mm, stroke of the rod: 500 mm, working pressure: 30 MPa | |

| Piston diameter: 100 mm, stroke of the rod: 800 mm, working pressure: 35 MPa |

Note: prices are indicative and can vary depending on the manufacturer, quality and volume of the order.

How to choose a reliable supplierhydraulic cylinders in China

The choice of a reliable supplier is an important step for successful purchasehydraulic cylinders. It is recommended to pay attention to the following factors:

- Work experience and reputation: Choose suppliers with many years of experience in the market and positive reviews from other customers.

- The presence of quality certificates: Make sure that the supplier has the necessary certificates of compliance with international quality standards (ISO 9001, etc.).

- Warranty and service: Clarify the warranty conditions and the availability of service.

- Assortment of products: A wide range of products allows you to choose the optimal cylinder for your specific task.

- Customer reviews: Read the reviews of other customers about working with the supplier.

Where to buyHydraulic cylinders for rotary mills in China?

There are several ways to purchasehydraulic cylinders for rotary mills in China:

- Visiting exhibitions and fairs: Participation in specialized exhibitions allows you to personally get acquainted with manufacturers and get acquainted with their products.

- Search on the Internet: Use search engines to search for manufacturers and suppliershydraulic cylinders in China. Pay attention to the site LLC Internal Mongolia Zhitsyan Construction equipmenthttps://www.nmgrq.ru/To familiarize yourself with the proposed assortment and technical characteristics of products.

- Appeal to trading companies: trading companies specializing in the supply of equipment fromChina, can help you find a suitable supplier and organize delivery.

Conclusion

When choosingHydraulic cylinder for rotary milling in Chinait is necessary to take into account many factors affectingpriceand product quality. A thorough analysis of the market, taking into account the technical characteristics and the choice of a reliable supplier will allow you to acquire an optimal solution that meets your needs and budget.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling products-

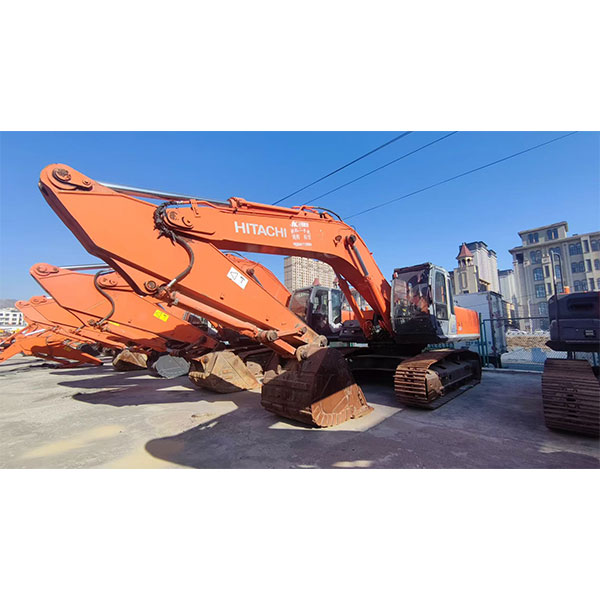

Restored Hitachi 240-3-102192

Restored Hitachi 240-3-102192 -

Carter 320D2L

Carter 320D2L -

Rail

Rail -

Hydraulic oil

Hydraulic oil -

Too heavy 80

Too heavy 80 -

Hitachi 360-3G with scissors with a tip, like an eagle beak 100128

Hitachi 360-3G with scissors with a tip, like an eagle beak 100128 -

19 Hitachi year 300-100517

19 Hitachi year 300-100517 -

Hydraulic details

Hydraulic details -

Hitachi 470h-3-100006

Hitachi 470h-3-100006 -

22 Khitachi year 690-100211

22 Khitachi year 690-100211 -

Hitachi 450h-101893

Hitachi 450h-101893 -

Restored steel graph with electric suction cups 100097

Restored steel graph with electric suction cups 100097

Connectedsearch

Related search- Cylinders with a large arrow and a small arrow in China

- Chinese factories for the production of non -standard hydraulic cylinders

- Cheap welding cylinder of manufacturers

- Chinese supplier of the new excavator

- OEM suppliers Mountain excavator

- Buy a hydraulic cylinder for a lift

- Chinese supplier of spare parts for excavators

- Cheap suppliers of excavators with a hydraulic mine

- Excavator Carter price in China

- Buy a hydraulic mine for an excavator-loader: a search query for those who want to purchase equipment [1] [2]