Economically effective hydraulic cylinder

Choiceeconomically effective hydraulic cylinderIt requires a thorough analysis of several factors, including cost, performance, reliability and durability. The optimization of these aspects allows you to reduce the total cost of operating equipment and increase its effectiveness. In this article, we will consider key selection criteria and provide practical recommendations for making a reasonable decision.

What's happenedeconomically effective hydraulic cylinder?

Economically effective hydraulic cylinder- This is a device that provides an optimal ratio between the cost of acquiring, operation and maintenance, and at the same time reliably performs its functions. Economic efficiency does not mean the lowest price, but involves the maximum return on investment throughout the cylinder life cycle.

Key factors affecting economic efficiency

The cost of acquisition

The initial cost is certainly an important factor. However, do not focus only on the lowest price. Cheap cylinders can be made of less high -quality materials and have a short service life, which will ultimately lead to higher replacement and repair costs. It is worth considering the cylinders from trusted manufacturers, such asLLC Internal Mongolia Zhitsyan Construction equipmentwho offer an optimal combination of price and quality.

The cost of operation

The cost of operation includes electricity costs or hydraulic fluid, as well as regular maintenance. Choose cylinders with high energy efficiency and low service requirements. For example, the use of seals with a low friction coefficient can reduce energy loss and reduce wear.

Reliability and durability

Reliability and durability are critical parameters. The longer the cylinder lasts without breakdowns, the less the cost of repair and replacement will be. Pay attention to the quality of materials, the design and the availability of protection against corrosion and wear. Cylinders fromLLC Internal Mongolia Zhitsyan Construction equipmentThey are made of high -quality materials, which ensures their durability.

The cost of maintenance and repair

Even the most reliable cylinders need maintenance and, sooner or later, in the repair. Find out how easily the spare parts are available and how qualified the staff capable of carrying out repairs. Choose the cylinders that are easily versed and collected, and for which there are maintenance instructions.

How to choose the right oneHydraulic cylinder

The choice of a suitable cylinder requires a thorough analysis of operating conditions and technical requirements. Consider the main parameters:

Determination of the necessary parameters

- Working pressure:Determine the maximum pressure in the hydraulic system.

- The diameter of the cylinder and the piston stroke:Calculate the necessary values based on the required effort and movement.

- Type of fastening:Select the appropriate type of fastening based on the design of the equipment (flange, articulated, etc.).

- Working environment:Consider the type of hydraulic fluid and environmental conditions (temperature, humidity, presence of aggressive substances).

The choice of material

The material of the cylinder must comply with the operating conditions. For standard conditions, carbon steel is suitable, for aggressive media - stainless steel or special alloys. Pistons are often made of cast iron or aluminum.

Seals

The seals play a key role in ensuring the tightness and durability of the cylinder. Choose seals compatible with hydraulic fluid and resistant to wear. The most common are seals made of rubber, polyurethane and PTFE.

Calculation of the cost of the life cycle

For evaluationeconomic efficiencyIt is necessary to calculate the cost of the cylinder life cycle. This includes the cost of acquisition, operation, maintenance and repair, as well as the cost of disposal. Compare the cost of the life cycle of various cylinder models to choose the most profitable option.

| Parameter | Cylinder a | Cylinder b |

|---|---|---|

| The cost of acquisition | 10,000 rubles. | 12 000 rub. |

| Operation cost (over 5 years) | 5 000 rub. | 4 000 rub. |

| The cost of maintenance and repair (over 5 years) | 3,000 rubles. | 1,000 rub. |

| The cost of utilization | 500 rub. | 500 rub. |

| The total cost of the life cycle | 18 500 rub. | 17 500 rub. |

*Example. Actual values may differ depending on the specific model and operating conditions.

Examples of successful applicationeconomically effective hydraulic cylinders

Consider several examples of applicationeconomically effective hydraulic cylindersIn various industries:

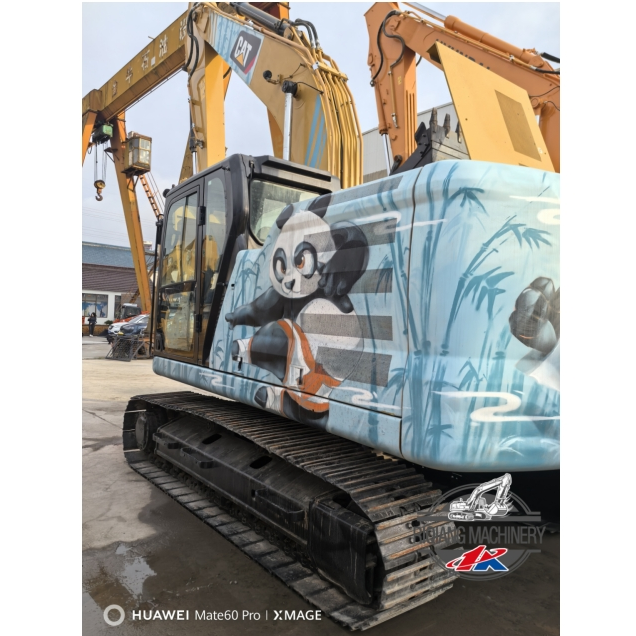

Construction equipment

In construction equipment, such as excavators and bulldozers, hydraulic cylinders are used for lifting and moving goods. Choiceeconomically effective cylindersAllows you to reduce fuel costs and increase productivity. CompanyLLC Internal Mongolia Zhitsyan Construction equipmentIt offers a wide range of cylinders for construction equipment that is highly reliable and durable.

Industrial equipment

In industrial equipment, hydraulic cylinders are used to automate various processes, such as stamping, pressing and casting. Usageeconomically effective cylindersAllows you to reduce electricity costs and maintenance. An example is the use of cylinders with a system of energy recovery, which allow you to return part of the energy spent on the piston movement back to the system.

Agricultural equipment

In agricultural machinery, hydraulic cylinders are used to control various hinged tools, such as plows, harrows and seeders. Choiceeconomically effective cylindersAllows you to reduce the cost of repair and maintenance of equipment. It is important to choose cylinders resistant to corrosion and pollution.

Recommendations for operation and maintenance

Proper operation and regular maintenance allow you to extend the service life of the hydraulic cylinder and reduce the cost of repairs. Here are a few recommendations:

- Regularly check the level of hydraulic fluid.

- Follow the purity of hydraulic fluid.

- Lubricate the movable parts of the cylinder.

- Regularly check the condition of the seals.

- Do not allow the cylinder overload.

Conclusion

Choiceeconomically effective hydraulic cylinder- This is a difficult task that requires the accounting of many factors. A thorough analysis of technical requirements, operating conditions and the cost of the life cycle will allow you to make the right choice and reduce the total cost of operating equipment. Contact specialistsLLC Internal Mongolia Zhitsyan Construction equipmentTo obtain a professional consultation and select the optimal solution.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Cheap cylinder.

- Leading Chinese buyers of custom -made hydraulic cylinders with double rod

- Chinese suppliers of excavator bucket cylinders

- Export prices used by excavators

- Chinese manufacturers of hydraulic cylinders for excavators

- Chinese supplier of a mini-excavator

- Cylinders for fork loaders for logistics equipment

- Cheap Avito excavator loader price

- Leading buyers of welding cylinders from China

- Cheap price of an excavator rental in Moscow