Products

18 years of Sanya 365-29818

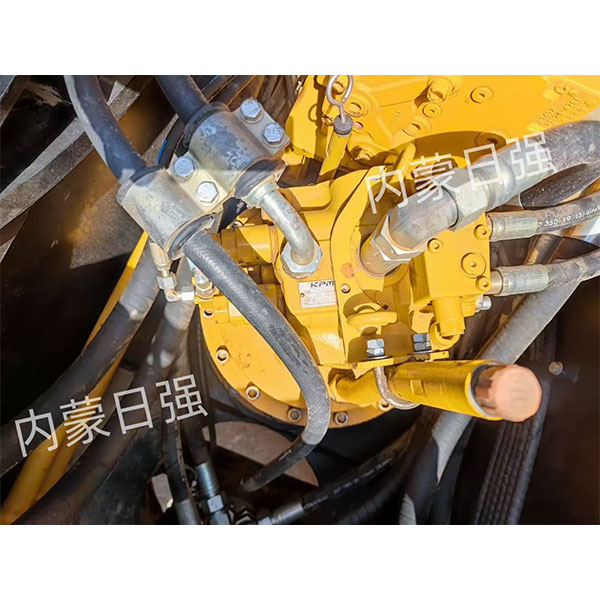

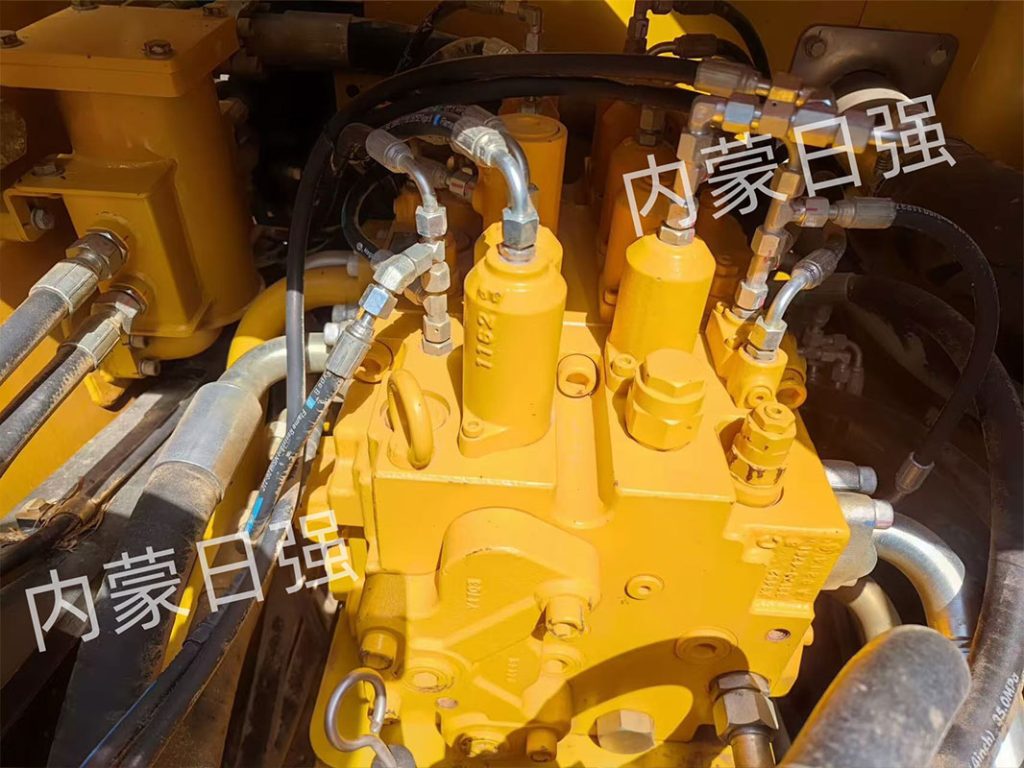

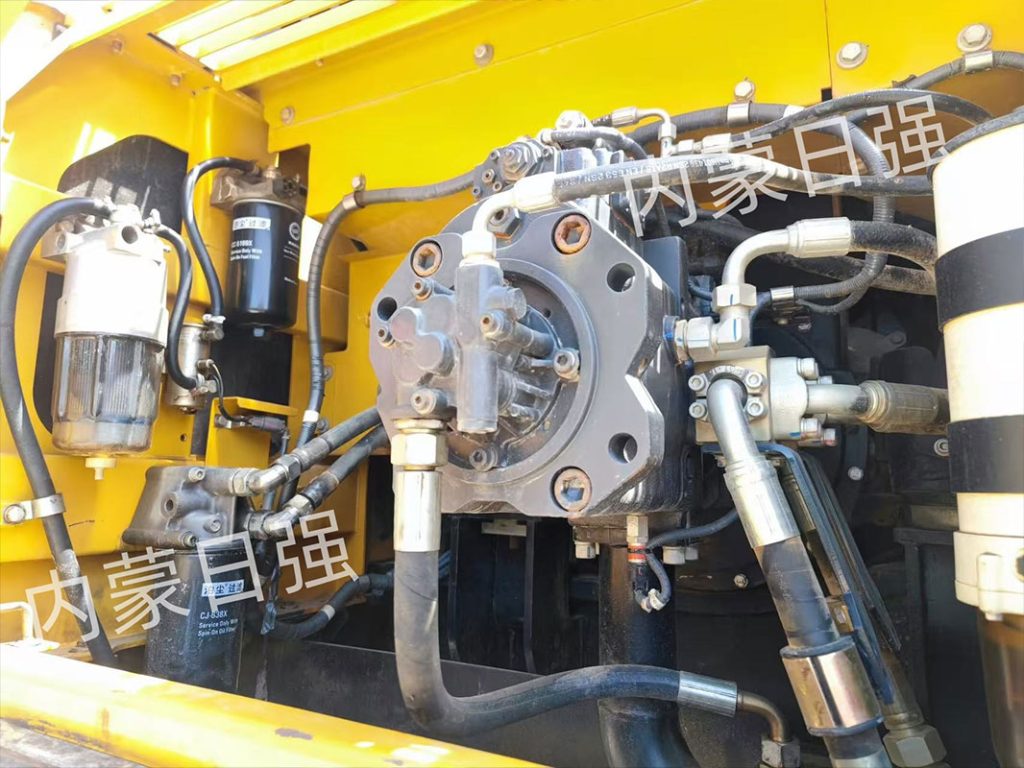

It was manufactured in 2018, the production of 8900 hours, the counterweight is painted, the remaining parts with the original paint, it works normally, the volume of the bucket is 1.6 cubic meters, was used on a stone career.