220 in a hydraulic power supply

Looking for reliable220 in a hydraulic power supply? Our article contains a detailed guide to the selection and use of hydraulic pumping stations 220V. You will learn about key characteristics, areas of application and advantages of using hydraulic systems with power from 220V.

What's happened220 in a hydraulic power supply?

220 in a hydraulic power supply, also known as the hydraulic pumping station, is an autonomous source of hydraulic energy. It consists of an electric motor, a hydraulic pump, a tank for oil, control valves and other components necessary to create and maintain hydraulic pressure. Food from the 220 V network makes it convenient for use in places where there is no access to three -phase meals.

Areas of use of hydraulic pumping stations 220V

The hydraulic pumping stations 220V are widely used in various industries and in everyday life. Some of the most common areas of application include:

- Construction:The rise and movement of heavy cargo, work with hydraulic tools, such as jacks and presses.

- Production:Management of hydraulic presses, machines and other equipment.

- Automobile industry:Raising cars on lifts, working with hydraulic brake systems.

- Agriculture:Management of hydraulic systems of tractors and other agricultural machinery.

- Household application:Work with hydraulic shifters, lifting mechanisms and other equipment.

Advantages of use220 in the hydraulic power supply

The use of hydraulic pumping stations 220V has a number of advantages compared to other types of hydraulic systems:

- Ease of use:A simple connection to a standard electric network 220V.

- Compactness:Compact design allows you to easily install and move the power supply.

- Reliability:Hydraulic systems are highly reliable and durable.

- Universality:A wide range of application in various industries.

- Safety:Safe work thanks to built -in protection systems from overload and short circuit.

How to choose220 in a hydraulic power supply

When choosing220 in the hydraulic power supplySeveral key factors must be taken into account:

Pump performance

The productivity of the pump, measured in liters per minute (l/min), determines the flow rate of hydraulic fluid. Select a pump with a performance sufficient for your equipment.

Working pressure

The working pressure measured in bars (bar) or megapascals (MPa) determines the maximum pressure that the power supply can create. Make sure that the selected working pressure meets the requirements of your equipment.

The volume of the tank

The volume of the tank determines the amount of hydraulic fluid, which can be stored in the power supply. The larger volume of the tank may be necessary for systems with a long time of operation or for systems requiring a large volume of fluid.

Engine power

The engine power, measured in kilowatts (kW) or horsepower (L.S.), determines the power necessary for the pump drive. Select the engine with sufficient power to provide the required pump performance.

Type of control valves

The type of control valves determines the methods of controlling the flow of hydraulic fluid. Various types of control valves allow you to perform various functions, such as adjusting the speed, direction and pressure pressure.

Example of control valves:

- Direction of the valve: controls the direction of motion of hydraulic fluid.

- Adjusting valve: regulates the consumption of hydraulic fluid.

- SUCHROOD CLAP: limits the maximum pressure in the system.

Additional functions

Some220 in hydraulic power suppliescan have additional functions, such as:

- Remote control.

- Digital display.

- Automatic shutdown during overload.

- Oil cooling system.

Examples of models220 in hydraulic power supplies

There are many models on the market220 in hydraulic power suppliesfrom various manufacturers. When choosing a suitable model, it is recommended to familiarize yourself with the technical characteristics and reviews of users.

As an example, we consider several popular models:

| Model | Performance (l/min) | Working pressure (bar) | Tank volume (l) | Engine power (kW) |

|---|---|---|---|---|

| Model a | 2 | 160 | 5 | 1.1 |

| Model b | 4 | 200 | 10 | 1.5 |

| Model C. | 6 | 250 | 20 | 2.2 |

Maintenance220 in the hydraulic power supply

Regular maintenance220 in the hydraulic power supplyIt is necessary to ensure it reliable and durable work. The main maintenance measures include:

- Regular verification of oil level and its replacement in accordance with the recommendations of the manufacturer.

- Checking and replacing filters.

- Checking and lifting joints.

- Checking and adjusting control valves.

- Cleaning the power supply of dirt and dust.

Where to buy220 in a hydraulic power supply?

You can buy220 in a hydraulic power supplyFor various suppliers, including:

- Specialized hydraulic equipment stores.

- Online stores.

- Hydraulic equipment manufacturers.

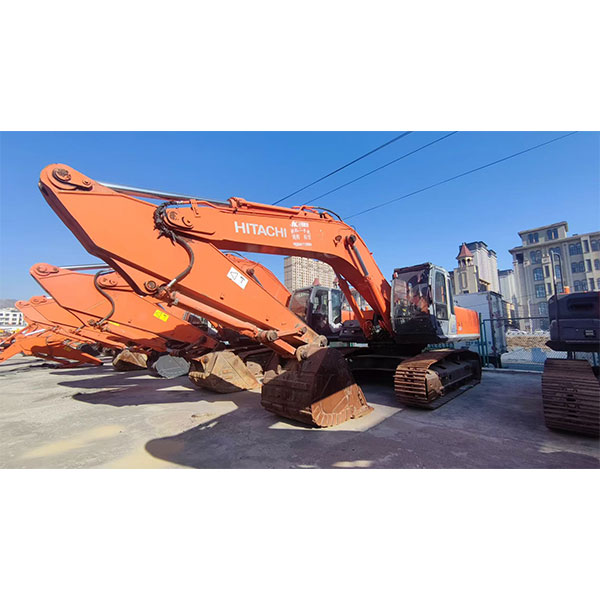

We recommend paying attention to the companyLLC Internal Mongolia Zhitsyan Construction equipmentspecializing in the supply of high -quality construction equipment, including220 in hydraulic power supplies.

Conclusion

220 in a hydraulic power supply- This is a reliable and universal source of hydraulic energy, widely used in various industries and in everyday life. When choosing a power supply, it is necessary to take into account factors such as the productivity of the pump, working pressure, volume of the tank, engine power and type of control valves. Regular maintenance provides reliable and durable operation of the power supply.

AppropriateProducts

Corresponding products

The best soldproducts

The best -selling productsConnectedsearch

Related search- Chinese cylinders production plants with nitrogenized piston rod

- Cheap main buyers of a lifting cylinder

- Hydrogener (synonyms): the search for synonyms of the term of the hydraulic mill itself can give additional options such as a hydraulic hammer

- The price of the Avito excavator in China

- Leading Chinese buyers of multi -stage cylinders

- Mini-excavator

- Professional production of the cylinder

- The main buyers of cylinders for construction equipment in China

- Chinese suppliers of solutions for hydraulic cylinders

- Cheap price Nissan Mini Excavator of Spare parts