Laser cutting flexion of St. Petersburg: where to order high -quality metal processing

2025-05-26

- What's happenedLaser cuttingAnd the bending of metal?

- What materials are suitable forlaser cuttingand flexible?

- Where to orderlaser cutting flexion St. Petersburg: Criteria for choosing a contractor

- Prices onlaser cutting flexion St. Petersburg

- Stages of working with the company onlaser cutting flexion St. Petersburg

- Examples of applicationlaser cuttingand flexible metal

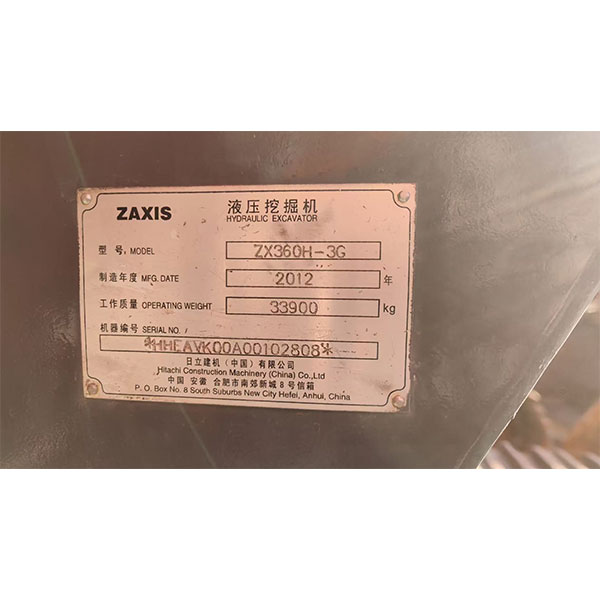

- LLC Internal Mongolia Zhitsyan Construction equipment and metal processing

- Tips for optimizing costs forlaser cutting flexion St. Petersburg

- Conclusion

- Comparison of various metal cutting methods

Looking for a reliable partner forlaser cuttingAndFast of metalIn St. Petersburg? In this article we will talk about key aspects of choosing a contractor, technology and materials, as well as give useful tips to optimize the costs oflaser cutting flexion St. Petersburg.

What's happenedLaser cuttingAnd the bending of metal?

Laser cutting- This is a modern method of cutting sheet metal using a focused laser beam. It provides high accuracy, speed and quality of cut, allows you to make parts of a complex form with minimal waste. The bending of the metal, in turn, gives flat workpieces the necessary geometry using special equipment, without violating the structure of the material.

Advantageslaser cutting

- High accuracy and repeatability

- The possibility of processing complex contours

- The minimum zone of thermal exposure

- Lack of mechanical contact with the material

- High cutting speed

Advantages of flexion of metal

- Formation of parts of complex geometry

- Preservation of the strength of the material

- High accuracy of bending

- Automation of the process

What materials are suitable forlaser cuttingand flexible?

Laser cuttingAnd bending is suitable for a wide range of metals, including:

- Carbon steel (ST3, ST20, 09G2C, etc.)

- Stainless steel (AISI 304, AISI 316, AISI 321, etc.)

- Aluminum and its alloys (AMG2, AMG3, D16T, etc.)

- Copper and its alloys (brass, bronze)

Where to orderlaser cutting flexion St. Petersburg: Criteria for choosing a contractor

The choice of a contractor forlaser cutting flexion St. Petersburg- Responsible task. Here are a few key criteria that you should pay attention to:

- Work experience and reputation:Find out how long the company has been working on the market, what reviews of customers, whether there are positive examples of completed projects.

- Technical equipment:Make sure the company has modern equipment forlaser cuttingAnd the bends of the metal that allows you to fulfill orders of any complexity.

- Staff qualifications:It is important that experienced specialists who have the necessary knowledge and skills work in the company.

- Terms of execution of the order:Specify what terms of the order execution the company offers, and how much they meet your requirements.

- Prices:Compare the prices of various companies, but remember that too low the price may indicate low quality of services.

- Additional services:Find out if the company provides additional services, such as design, painting, delivery and installation.

Prices onlaser cutting flexion St. Petersburg

Pricelaser cutting flexion St. PetersburgDepends on several factors, including:

- Type and thickness of metal

- The complexity of the contour of the part

- The volume of the order

- The urgency of the execution of the order

To obtain an exact cost, it is recommended to send drawings of parts to several companies and request a commercial offer.

Stages of working with the company onlaser cutting flexion St. Petersburg

- Providing drawings or sketches:You send the companies drawings or sketches of parts that need to be made.

- Calculation of cost:The company calculates the cost of the order and agrees it with you.

- Preparation of production:The company prepares equipment and materials for the execution of the order.

- Laser cuttingAnd bending:ProducedLaser cuttingAnd the bending of the metal in accordance with the drawings.

- Quality control:Quality control of finished parts is performed.

- Delivery:Ready -made details are delivered to you.

Examples of applicationlaser cuttingand flexible metal

Laser cuttingAnd the bending of metal is widely used in various industries, including:

- Mechanical engineering

- Instrumentation

- Construction

- Advertising industry

- Furniture production

- Electronics

For example, with the helplaser cuttingThe housings of devices, parts of machines, elements of facades of buildings, advertising structures and much more are made.

LLC Internal Mongolia Zhitsyan Construction equipment and metal processing

Although our company, internal Mongolia Zhitsyan Construction equipment (https://www.nmgrq.ru/), specializes in construction equipment, we understand the importance of high -quality metal processing for various industries. Founded in 2000 and having more than 200 employees and 5 branches in internal Mongolia, our company seeks to provide high -quality solutions for our customers. Consider the importancelaser cutting of flexion St. Petersburgfor the production of high -quality construction machines.

Tips for optimizing costs forlaser cutting flexion St. Petersburg

- Optimize the drawings:Simplify the contours of parts and minimize the amount of waste.

- Order large volumes:With large volumes of order, you can get a discount.

- Choose optimal material:Use the most suitable material for your task to avoid unnecessary costs.

- Plan the orders in advance:Avoid urgent orders that are usually more expensive.

Conclusion

Laser cutting flexion St. Petersburg- This is an effective way of processing metal, which allows you to make parts of high accuracy and quality. When choosing a contractor, pay attention to his experience, technical equipment, staff qualifications and prices. We hope that this article helped you understand the main aspectslaser cuttingand flexible metal.

Comparison of various metal cutting methods

Consider the comparison tablelaser cuttingWith other popular metal cutting methods:

| Cutting method | Accuracy | Speed | The complexity of the contour | Price |

|---|---|---|---|---|

| Laser cutting | High | High | Complex contours | Average |

| Plasma cutting | Average | High | Limited | Low |

| Hydroabraseic cutting | High | Low | Complex contours | High |

| Mechanical cutting | Low | Low | Simple contours | Low |

As can be seen from the table,Laser cuttingIt offers the optimal combination of accuracy, speed and cost for most tasks.

Table data source:It is based on generalized experience and open sources in the field of metalworking. Exact parameters can vary depending on specific equipment and materials.