Laser cutting and bending of metal in St. Petersburg: a full guide for the choice and order of services

2025-05-26

- What's happenedlaser cutting and bending metal?

- What materials are suitable forlaser cutting and bending?

- How to choose a company forlaser cutting and bending of metal in St. Petersburg?

- Where to orderlaser cutting and flexion of metal in St. Petersburg?

- Prices onlaser cutting and flexion of metal

- How to prepare drawings forlaser cutting and bending metal?

- Conclusion

Looking for a reliable partner forlaser cutting and bending of metal in St. Petersburg? Our article will help you understand technologies, materials and prices, as well as choose a suitable company that offers quality services and optimal terms of execution of orders.

What's happenedlaser cutting and bending metal?

Laser cutting of metal- This is a modern and high -precision method of cutting sheet metal using a laser beam. This process allows you to create parts of a complex form with minimal tolerances.Flying metal- This is the process of changing the shape of sheet metal at a certain angle, also widely used in metalworking.

Advantageslaser cutting

- High accuracy and quality of cut

- The possibility of processing various materials (steel, aluminum, stainless steel, etc.)

- Minimum loss of material

- High cutting speed

- The possibility of creating complex geometric shapes

AdvantagesFast of metal

- Obtaining parts of the desired form with high accuracy

- The possibility of bending of various materials

- Preservation of the strength of the material in the place of GIB

- Economic production

What materials are suitable forlaser cutting and bending?

Technologieslaser cutting and bending metalApply to a wide range of materials. The most common of them:

- Steel (carbon, stainless, galvanized)

- Aluminum and its alloys

- Copper and its alloys (brass, bronze)

- Titanium

The choice of material depends on the specific requirements for the part: strength, corrosion resistance, weight, etc.

How to choose a company forlaser cutting and bending of metal in St. Petersburg?

The choice of a suitable company is an important step for the successful implementation of your project. Pay attention to the following factors:

- The experience and reputation of the company:Find out how long the company has been working on the market, and read customer reviews.

- Equipment:Make sure that the company has modern and high -precision equipment forlaser cutting and bending metal.

- Staff qualifications:It is important that the company's specialists have the necessary knowledge and experience to perform complex tasks.

- Terms of execution of orders:Check the deadlines for your order and make sure that they suit you.

- Prices:Compare services for serviceslaser cutting and bending metalDifferent companies choose the best option.

- Additional services:Find out if the company offers additional services, such as design, painting, welding, etc.

Where to orderlaser cutting and flexion of metal in St. Petersburg?

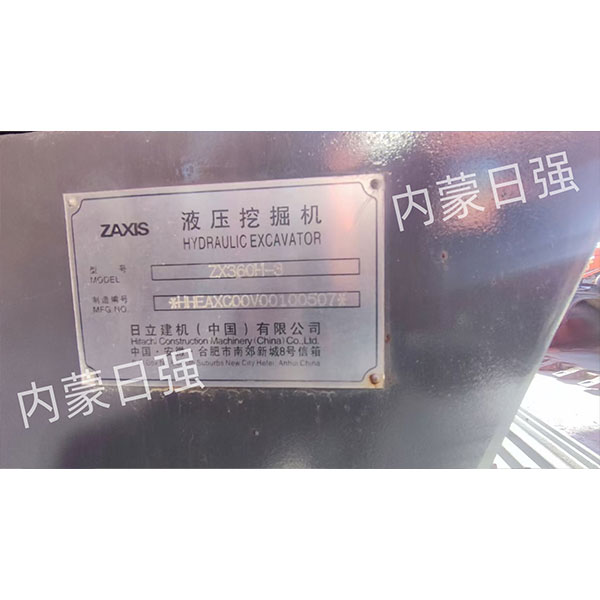

In St. Petersburg, a wide selection of companies offering services is presentedlaser cutting and bending metal. When choosing a contractor, we recommend that you familiarize yourself with the company's portfolio, request work samples and clarify all the questions you are interested in. LLC Internal Mongolia Zhitsyan Construction equipment, a company with a rich history, founded in 2000 and having 5 branches in internal Mongolia, may also be a useful partner in the implementation of projects related to metalworking. The company's headquarters, located in the Zinchuan development zone, the city of Huh-Khoto, occupies an area of 35,000 square meters, which indicates a serious scale of production. Link to the company's website:https://www.nmgrq.ru/

Prices onlaser cutting and flexion of metal

Pricelaser cutting and bending metalDepends on several factors:

- Type and thickness of the material

- The complexity of the geometry of the part

- The volume of the order

- The urgency of the execution of the order

To obtain accurate value, it is necessary to provide drawings or sketches of parts to the company providing serviceslaser cutting and bending metal.

Approximate prices forLaser cutting(per meter cut)

| Material | Thickness, mm | Price, rub./Meter |

|---|---|---|

| Steel is carbon | 1 | From 50 |

| Stainless steel | 1 | From 70 |

| Aluminum | 1 | From 80 |

Prices are indicated and may vary depending on the company and the volume of the order.

Approximate prices forFlexible metal(for the firm)

| Material | Thickness, mm | Price, rub |

|---|---|---|

| Steel is carbon | 1 | From 30 |

| Stainless steel | 1 | From 40 |

| Aluminum | 1 | From 50 |

Prices are indicated and may vary depending on the company and the volume of the order.

How to prepare drawings forlaser cutting and bending metal?

Properly prepared drawings are the key to successful execution of the order. It is recommended to provide drawings in vector format (for example, DXF, DWG). Drawings should contain the following information:

- The size of the details

- The thickness of the material

- GIB angles (for bumps of metal)

- Tolerances

- Surface roughness (if required)

In the absence of drawings, many companies offer services for the development of drawings based on sketches or samples of parts.

Conclusion

Laser cutting and bending metal- These are effective and modern technologies that allow you to make details of a complex form with high accuracy. When choosing a company to fulfill your order, pay attention to the experience and reputation of the company, equipment, staff qualifications, deadlines for ordering and price. We hope that our article helped you understand the main aspectslaser cutting and bending of metal in St. Petersburg.