Laser cutting with flexible: opportunities and advantages

2025-05-26

- What's happenedlaser cutting with flexible?

- Advantageslaser cutting with flexible

- Areas of applicationlaser cutting with flexible

- The choice of equipment forlaser cutting with flexible

- Examples of applicationlaser cutting with flexible

- Why is it worth contacting LLC inner Mongolia Zhitsyan Construction equipment forlaser cutting with flexible?

- Technical characteristics of equipment forlaser cutting

- Conclusion

Laser cutting with flexible- This is an advanced technology that allows you to process the sheet metal of various thicknesses and shapes with high accuracy and speed. It combines the advantages of laser cutting and flexibility, providing ample opportunities for the production of parts of complex geometry. LLC Internal Mongolia Zhitsyan Construction equipment offers a wide range of services in the field of laser metal cutting. You can learn more about our capabilities onnmgrq.ru.

What's happenedlaser cutting with flexible?

Laser cutting with flexible- This is a process in which a laser beam is used to cut the contour of the part on sheet metal, which is then flexed to give the necessary shape. This method allows you to make complex three -dimensional parts from one sheet of metal, minimizing the number of welds and reducing production time.

The principle of work

Processlaser cutting with flexibleUsually consists of the following stages:

- Development of 3D models details:A digital model of the required part is created.

- Cutting sheet metal:Based on the 3D model, the cutting of sheet metal is developed taking into account the zones of the cut and bending.

- Laser cutting:The laser beam cuts out the contour of the part on the sheet metal.

- Fast:The part is flexible along the specified lines to give the final shape.

Advantageslaser cutting with flexible

Laser cutting with flexibleIt has a number of significant advantages compared to traditional metal processing methods:

- High accuracy:Laser cutting provides high cut accuracy, which allows you to make parts of complex geometry with minimal tolerances.

- High speed:The cutting process occurs at high speed, which reduces production time.

- Minimum waste:Optimized cutting of sheet metal allows minimizing the amount of waste.

- Universality:The technology is suitable for processing various materials, including steel, stainless steel, aluminum and others.

- Lack of mechanical contact:The laser beam does not contact the material, which excludes its deformation and damage.

- Integration of processes:The possibility of combining cutting operations and bending in one technological cycle.

Areas of applicationlaser cutting with flexible

Laser cutting with flexibleIt is widely used in various industries:

- Mechanical engineering:Making buildings, frames, brackets and other parts.

- Devices:Production of the housing of devices, control panels and other elements.

- Automotive industry:Production of body parts, interior elements and exterior.

- Aircraft Building:Production of elements of fuselage, wings and other structures.

- Construction:The manufacture of facade panels, roofing elements and other building structures.

- Household appliances:Production of hulls of household appliances, control panels and other elements.

The choice of equipment forlaser cutting with flexible

When choosing equipment forlaser cutting with flexibleThe following factors must be taken into account:

- Laser power:It is determined depending on the thickness and type of material.

- Lazer type:CO2 lasers are suitable for processing a wide range of materials, and fiber lasers provide higher speed and accuracy of cutting.

- Desktop size:It is determined depending on the size of the processed parts.

- Management system:It should be convenient and functional, provide accurate control of the cutting and bending process.

- Additional functions:Automatic Sopel change, a system for controlling the height of the cutting head, a laser cooling system.

Examples of applicationlaser cutting with flexible

Consider several specific examples of applicationlaser cutting with flexible:

- Production of housings for electronics: Laser cutting with flexibleAllows you to make complex houses for electronics with high accuracy and the minimum amount of welds.

- Production of parts for furniture:The technology allows you to make bent furniture elements of a complex shape of sheet metal.

- Making decor elements: Laser cutting with flexibleAllows you to create unique elements of metal decor, such as lamps, vases and other interior items.

Why is it worth contacting LLC inner Mongolia Zhitsyan Construction equipment forlaser cutting with flexible?

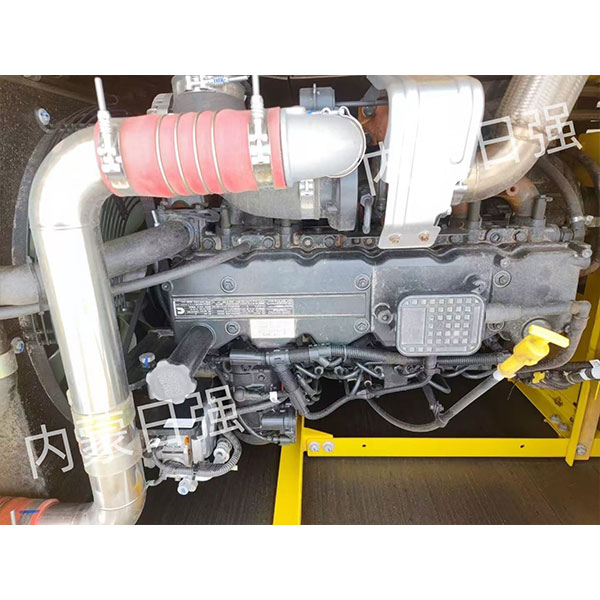

LLC Internal Mongolia Zhitsyan Construction equipment is a reliable partner in the field of metalworking. The company was founded in 2000 and has more than 200 employees. She has 5 branches in inner Mongolia. Its headquarters are located in the zone of development of Jinchuan, the city of Huh-Khoto, and occupies an area of 35,000 square meters. We offer:

- Modern equipment:Our equipment park includes modern machines forlaser cutting with flexibleFrom leading world manufacturers.

- Qualified personnel:Our experts have extensive experience in the field of metalworking and are ready to complete orders of any complexity.

- High quality:We guarantee high quality products and compliance with the deadlines for the execution of orders.

- Individual approach:We take into account all the wishes of the customer and offer optimal solutions for each specific case.

- Competitive prices:We offer competitive prices for all types of services.

Technical characteristics of equipment forlaser cutting

For example, we give the technical characteristics of one of the types of equipment used for laser cutting (data can vary depending on the manufacturer and model):

| Characteristic | Meaning |

|---|---|

| Laser power | 2000 - 6000 watts |

| Lazer type | Voloconial |

| The size of the desktop | 1500 x 3000 mm |

| The thickness of the processed material (steel) | up to 25 mm |

| Positioning accuracy | ± 0.03 mm |

The data are given for example and may differ depending on the specific equipment model. (Source: Data provided by LLC Internal Mongolia Zhitsyan Construction equipment)

Conclusion

Laser cutting with flexible- This is a modern and effective technology that allows you to make parts of complex geometry with high accuracy and speed. If you need high -quality and operationalLaser cuttingContact LLC inner Mongolia Zhitsyan Construction equipment. We are ready to offer you optimal solutions for any tasks.