The world's first electrical equipment for straightening the hair of the ZX470LCH-3 “Made in Zhitsyan” was released with honor.

2025-02-01

Solving technical problems and satisfying the urgent needs of customers - this is the unique approach of the company Zhitsyan from internal Mongolia!

December 6, 2013, after the company's annual technical efforts, the world's first electrified model ZX470LCH-3 was officially released. The equipment transfer ceremony was held at the factory. The main developers from the equipment restoration plant held deep discussions with customers, which contributed to the promotion of the electrical transformation of Hitachi excavators to a new level.

To solve the problem of the high frequency of fuel system failures and the electric system on excavators with Hitachi electrobenzine engines, under the leadership of the General Director of the Zhitsyan from internal Mongolia, a team of developers from key technical specialists of the restoration plant was created. They carried out the restoration of equipment, taking into account various working conditions, which made it possible not only to effectively satisfy the needs of mining customers in various devices, but also to extend the service life of their equipment. It also reduced the investment costs of customers and improved the turnover of funds. As a result, the negative effect of excavators with electrobenzine engines of the -3 series was eliminated, and the owners of the ZX470LCH -3 excavators now expect improvements in the efficiency of work and reduce service costs.

Recovery standards

1. After the restoration, a clear warranty period applies (6 months or 2000 hours, depending on what will come earlier).

2. The assembly of parts, the engine is converted into an engine with direct injection, hydraulic parts are disassembled, checked, repaired and painted. The electric part of the control is replaced by new details.

3. All rubber tubes that are slightly cracked, exfoliated or aged, will be replaced, and all the seals in all parts will be replaced.

4. Productivity: digging force, speed and control system comply with the standards of the new ZX450H-1 machine.

5. Appearance: almost new.

Recovery process

1. After receiving the car, the maintenance personnel will carry out a complete check of the operability of the vehicle, determine the damage in accordance with the recovery standards and draw up a maintenance plan.

2. Starting to maintenance work, the technical maintenance team must first distribute the tasks, dividing it into: a group of disassembling and assembling the entire machine, a group of disassembling and repairing assembly units. The grouping of structural parts and the assembly of each component throughout the repair process is carried out in accordance with the regulatory data of the Hitachi decoration manual. The introduction of standardized operations, repair concepts based on technological processes and the implementation of the recovery process.

Engine part

Replace the 6WG1 electronic injection with a direct injection of 6WG1 (ZX470H-5G).

Electric part

1. Replace the internal and external wire harnesses and the main controller (MC ECU).

2. Electric motor EC (engine control electric motor).

3. Install sensors and relay.

The hydraulic part

1. Disassemble, inspect and measure the pumps and hydraulic assembly engines in accordance with the recovery standards, continue to use parts within the data range on use and repair faulty parts. During the model experiment on the laboratory stand, its volumetric efficiency reached more than 95%. Accurate setting in accordance with the initial PQ curve.

2. When repairing the control valve, check all the hydraulic components in the control valve, while replacing the seals. By measuring and testing, return the leak, maintaining pressure, reversing and the functions of the control valve in the original state.

3. Disassemble, inspect and clean the gearbox, replace all seals.

4. Replace all seals and guide bushings of cylinders and central rotary hinges of the car. Check and correct the bending of the piston rod, repair the piston rods with a damaged surface.

5. After the repair, the outer part of the node will be painted with spraying.

The next step is walking and structural parts

1. Check the welds and cracks of steel plates in various parts of the chassis and front operating device.

2. The front part of the Khodunka frame is repaired and reinforced.

3. repair the fasteners and seats of the support wheels and stars (fixing bolts broken).

4. Modification of the protective casing of the chain.

5. Repair the type D platform and replace the type D.

6. Measures for maintenance, strengthening parts subject to breakdowns.

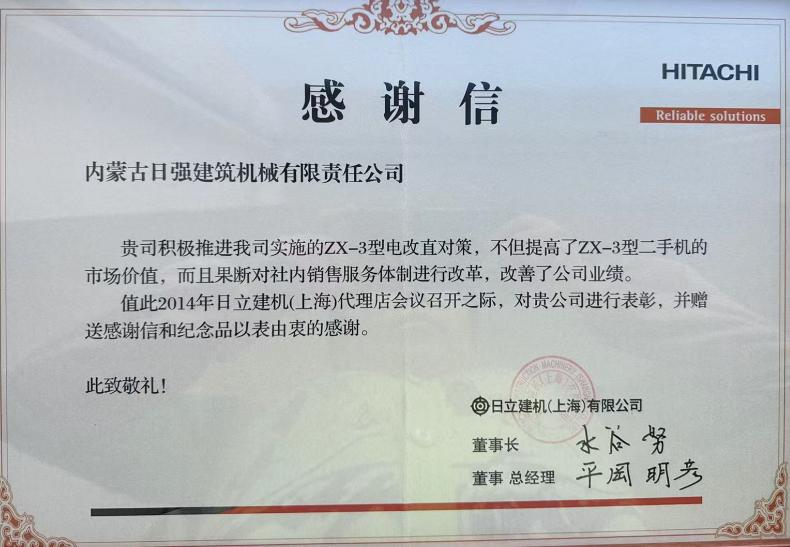

After the repair of the entire car, a test was carried out for the excavation of soil. The digging force, digging speed and engine control have reached the ZX450H-1 standard. The appearance also reached the recovery standard. The adaptability of a direct injection machine was significantly improved. The client used it for more than 500 hours without any problems and was pleased with the digging force, speed and general performance of the machine. After the modified equipment was launched on the market, Hitachi employees visited the place to see the effect of its use, and decided to develop and formulate a set for converting the ZX470LCH-3 electrical equipment and formulate a complete set, as well as promote a complete set. Technical data in the world, which is the ZX-3 equipment contributed to an increase in market value. In 2014, Hitachi thanked the internal Mongolia Zhitsyan for this act and gave him high.

This not only demonstrates the customer -oriented concept of servicing Inner Mongolia Riqiang, saves customer costs and gives equipment a new life cycle, but also reflects the technical power of Inner Mongolia Riqiang, from design, research and development to advance, maintenance of equipment and safe use is the best solution, which not only reduces the frequency of frequency Equipment failures, but also extends its service life, and also contributes to the technological updating of Hitachi products. Thanks to the exact analysis and understanding of the market, professional technical knowledge and a customer -oriented service concept, Inner Mongolia Riqiang will continue to provide professional individual solutions for the construction equipment industry.